EXHIBIT 99.1

Published on February 11, 2016

Axalta Coating Systems Ltd. Investor Presentation February 11, 2016 Exhibit 99.1

PROPRIETARY AXALTA COATING SYSTEMS 2 Forward-Looking Statements This presentation and the oral remarks made in connection herewith may contain “forward-looking statements” within the meaning of the U.S. Private Securities Litigation Reform Act of 1995, including those relating to sales, adjusted EBITDA, interest expense, normalized tax rate, diluted shares, cost and productivity savings, capital expenditures, plant expansions, working capital, return on invested capital, free cash flow and growth. Any forward-looking statements involve risks, uncertainties and assumptions. These statements often include words such as “believe,” “expect,” “anticipate,” “intend,” “plan,” “estimate,” “target,” “project,” “forecast,” “seek,” “will,” “may,” “should,” “could,” “would,” or similar expressions. These statements are based on certain assumptions that we have made in light of our experience in the industry and our perceptions of historical trends, current conditions, expected future developments and other factors we believe are appropriate under the circumstances as of the date hereof. Although we believe that the assumptions and analysis underlying these statements are reasonable as of the date hereof, investors are cautioned not to place undue reliance on these statements. We do not have any obligation to and do not intend to update any forward-looking statements included herein, which speak only as of the date hereof. You should understand that these statements are not guarantees of future performance or results. Actual results could differ materially from those described in any forward- looking statements contained herein or the oral remarks made in connection herewith as a result of a variety of factors, including known and unknown risks and uncertainties, many of which are beyond our control. Non-GAAP Financial Measures The historical financial information included in this presentation includes financial information that is not presented in accordance with generally accepted accounting principles in the United States (“GAAP”), including EBITDA, adjusted EBITDA and net debt. Management uses these non-GAAP financial measures in the analysis of our financial and operating performance because they assist in the evaluation of underlying trends in our business. Our use of the terms EBITDA, adjusted EBITDA and net debt may differ from that of others in our industry. EBITDA and adjusted EBITDA should not be considered as alternatives to net income (loss), operating income or any other performance measures derived in accordance with GAAP as measures of operating performance or operating cash flows or as measures of liquidity. EBITDA, adjusted EBITDA and net debt have important limitations as analytical tools and should be considered in conjunction with, and not as substitutes for, our results as reported under GAAP. This presentation includes a reconciliation of certain non-GAAP financial measures with the most directly comparable financial measures calculated in accordance with GAAP. Defined Terms All capitalized terms contained within this presentation have been previously defined in our filings with the United States Securities and Exchange Commission. Legal Notices

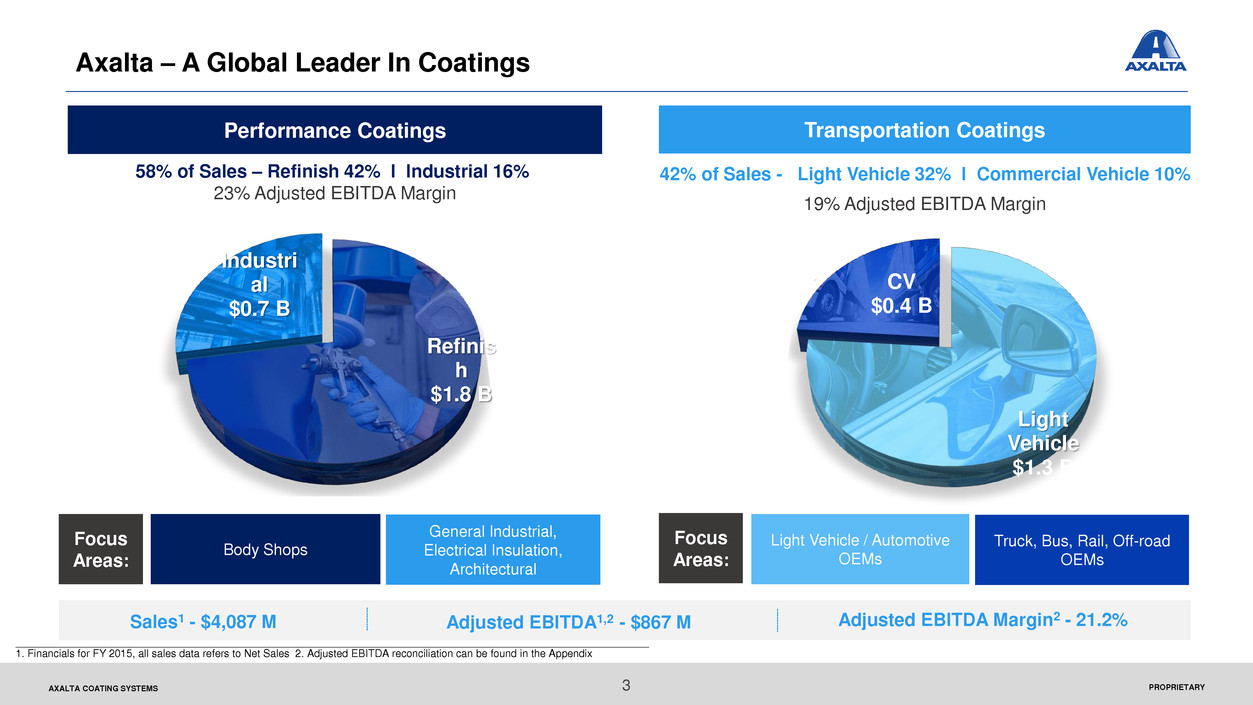

PROPRIETARY AXALTA COATING SYSTEMS Refinis h $1.8 B Industri al $0.7 B Body Shops Light Vehicle $1.3 B CV $0.4 B Performance Coatings General Industrial, Electrical Insulation, Architectural Transportation Coatings Sales1 - $4,087 M Adjusted EBITDA1,2 - $867 M Adjusted EBITDA Margin2 - 21.2% Light Vehicle / Automotive OEMs Truck, Bus, Rail, Off-road OEMs 58% of Sales – Refinish 42% l Industrial 16% 23% Adjusted EBITDA Margin Focus Areas: Focus Areas: 42% of Sales - Light Vehicle 32% l Commercial Vehicle 10% 19% Adjusted EBITDA Margin ____________________________________________________________________________________________________________ 1. Financials for FY 2015, all sales data refers to Net Sales 2. Adjusted EBITDA reconciliation can be found in the Appendix 3 Axalta – A Global Leader In Coatings

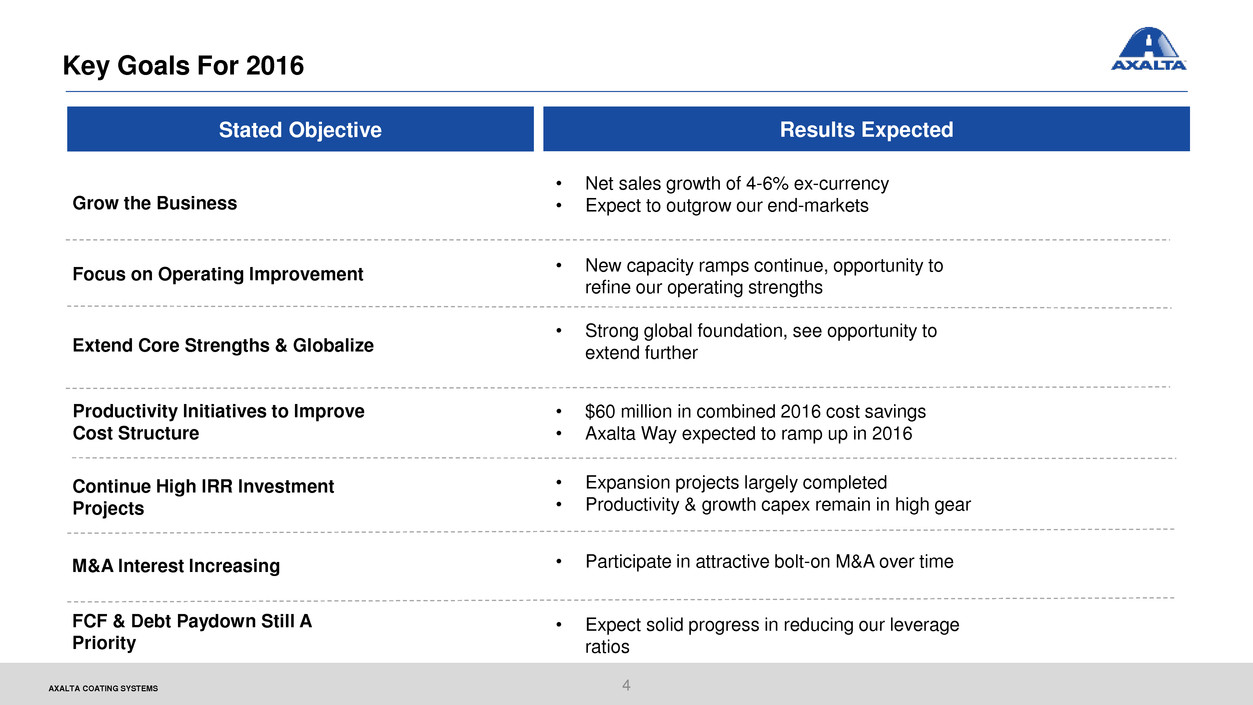

AXALTA COATING SYSTEMS Key Goals For 2016 Grow the Business Productivity Initiatives to Improve Cost Structure Focus on Operating Improvement Extend Core Strengths & Globalize • Net sales growth of 4-6% ex-currency • Expect to outgrow our end-markets • $60 million in combined 2016 cost savings • Axalta Way expected to ramp up in 2016 • New capacity ramps continue, opportunity to refine our operating strengths • Strong global foundation, see opportunity to extend further Continue High IRR Investment Projects • Expansion projects largely completed • Productivity & growth capex remain in high gear 4 M&A Interest Increasing • Participate in attractive bolt-on M&A over time FCF & Debt Paydown Still A Priority • Expect solid progress in reducing our leverage ratios Stated Objective Results Expected

PROPRIETARY AXALTA COATING SYSTEMS 5 Axalta Operates Fundamentally Strong Businesses A Global Leader in Our Markets Significant Competitive Advantages A Service-Led Business Model Structurally Attractive End Markets Highly Variable Cost Structure; Low Capital Intensity

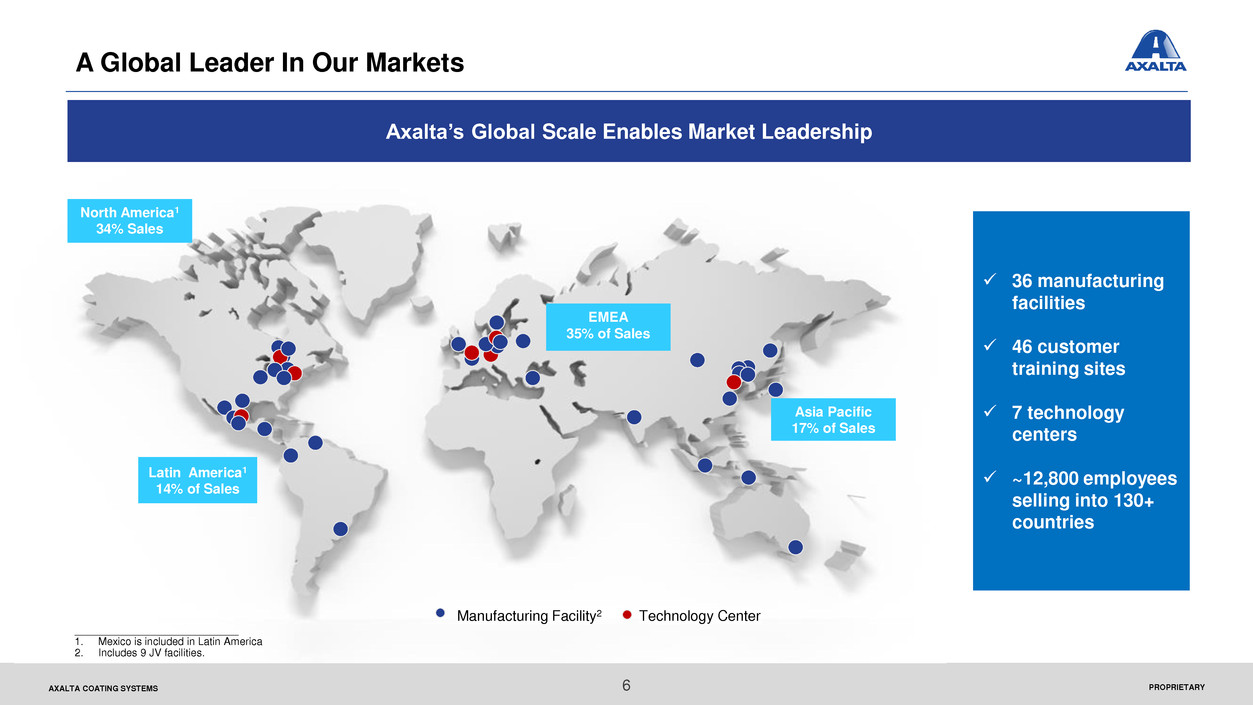

PROPRIETARY AXALTA COATING SYSTEMS 6 A Global Leader In Our Markets Axalta’s Global Scale Enables Market Leadership ____________________________ 1. Mexico is included in Latin America 2. Includes 9 JV facilities. 36 manufacturing facilities 46 customer training sites 7 technology centers ~12,800 employees selling into 130+ countries North America1 34% Sales Latin America1 14% of Sales Asia Pacific 17% of Sales EMEA 35% of Sales Manufacturing Facility2 Technology Center

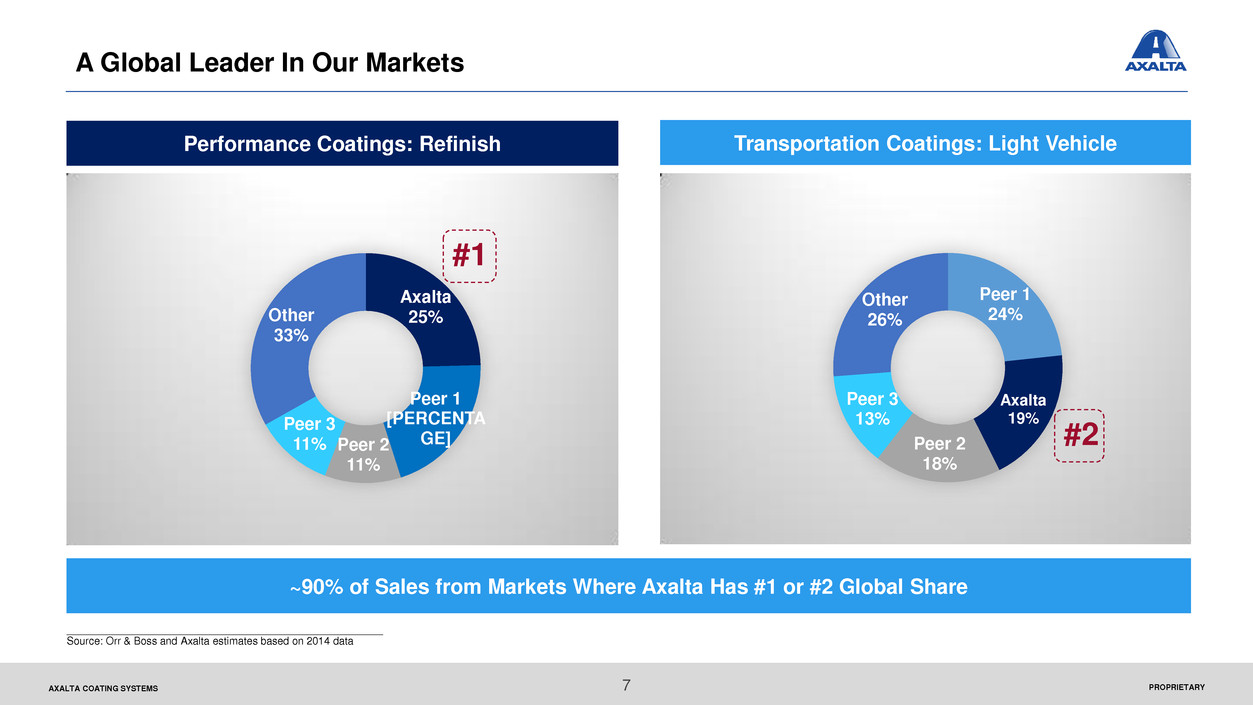

PROPRIETARY AXALTA COATING SYSTEMS Peer 1 24% Axalta 19% Peer 2 18% Peer 3 13% Other 26% 7 A Global Leader In Our Markets ~90% of Sales from Markets Where Axalta Has #1 or #2 Global Share Axalta 25% Peer 1 [PERCENTA GE] Peer 2 11% Peer 3 11% Other 33% Performance Coatings: Refinish Transportation Coatings: Light Vehicle #1 ______________________________________________________ Source: Orr & Boss and Axalta estimates based on 2014 data #2

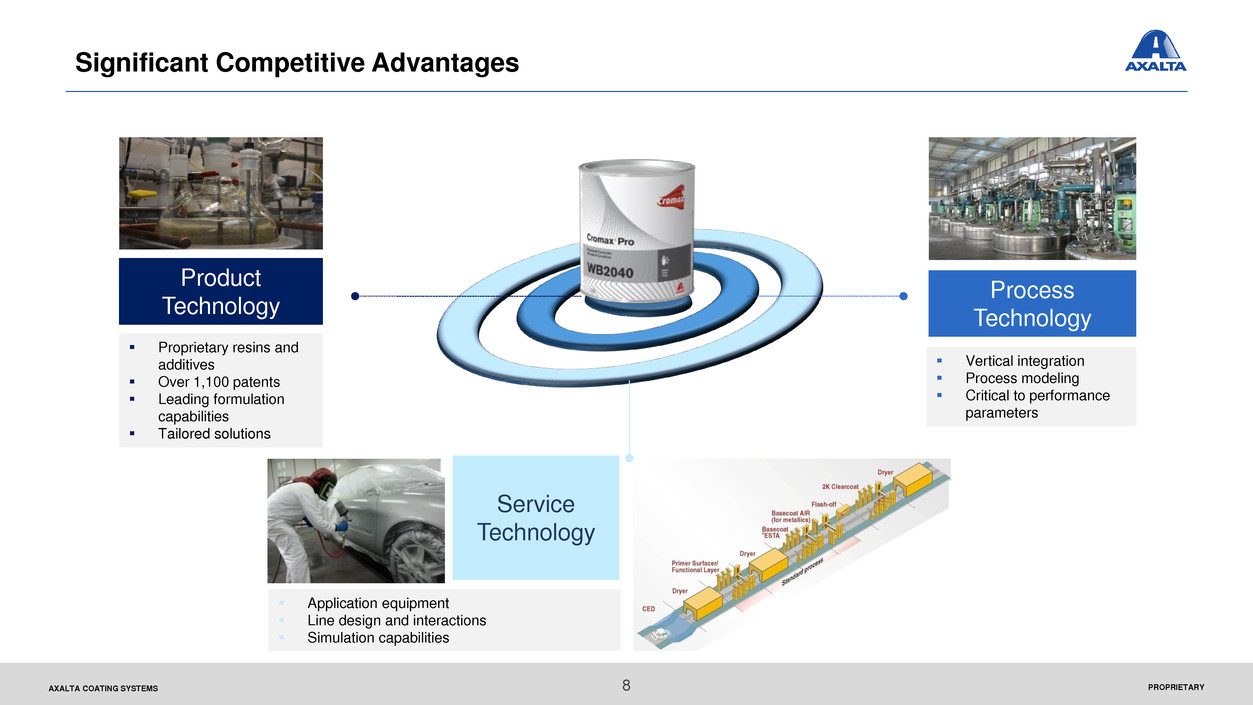

PROPRIETARY AXALTA COATING SYSTEMS Process Technology Service Technology Product Technology Proprietary resins and additives Over 1,100 patents Leading formulation capabilities Tailored solutions Application equipment Line design and interactions Simulation capabilities Vertical integration Process modeling Critical to performance parameters 8 Significant Competitive Advantages

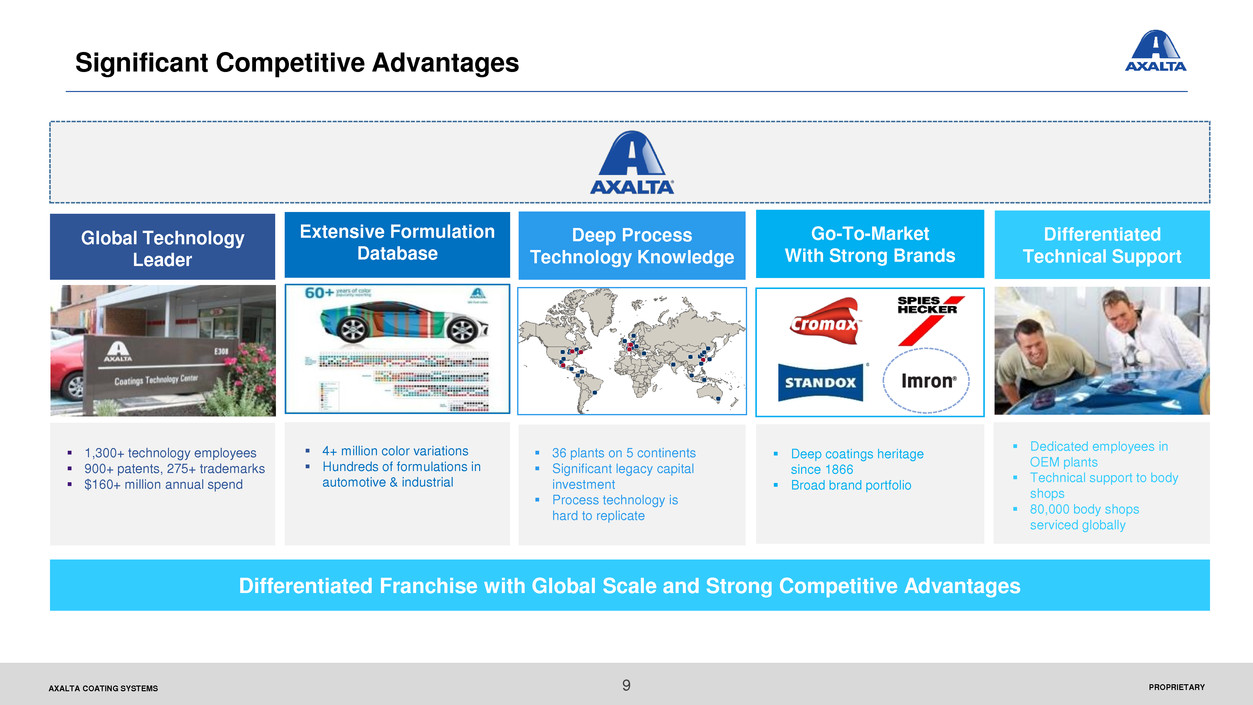

PROPRIETARY AXALTA COATING SYSTEMS 9 Significant Competitive Advantages Differentiated Franchise with Global Scale and Strong Competitive Advantages 4+ million color variations Hundreds of formulations in automotive & industrial Deep coatings heritage since 1866 Broad brand portfolio 1,300+ technology employees 900+ patents, 275+ trademarks $160+ million annual spend 36 plants on 5 continents Significant legacy capital investment Process technology is hard to replicate Dedicated employees in OEM plants Technical support to body shops 80,000 body shops serviced globally Global Technology Leader Extensive Formulation Database Deep Process Technology Knowledge Go-To-Market With Strong Brands Differentiated Technical Support

PROPRIETARY AXALTA COATING SYSTEMS Industry Trends Axalta Technologies OEM Vehicle Light-Weighting Broad substrate coating applicability for next generation materials Growth in Multi-Shop Operators (“MSO”) Axalta’s waterborne technology improves MSO productivity and our national coverage enables high service levels 10 Significant Competitive Advantages More Complex Colors Integration with OEMs grows color library Advanced color matching technologies critical to body shop supplier selection Our technology enables OEMs to reduce capital, footprint, headcount and energy OEMs Seek Continuous Productivity Improvement Government Regulation: VOC Limits Complete VOC compliant portfolio for both Refinish and OEM Broad Technology Portfolio Well-Positioned to Benefit From Industry Trends

PROPRIETARY AXALTA COATING SYSTEMS 11 Axalta Employs A Service-Led Business Model Critical Functionality at a Relatively Low Cost 1 Compelling Value Proposition Where Product Cost is Not the Main Driver Light & Commercial Vehicle: <1% of a new vehicle’s cost Industrial: Critical to function, durability, safety & compliance Refinish: 5%-10% of total repair cost Body Shop OEM Plant Service is Key in Both Refinish and OEM End-Markets Painter Training Shop Productivity Shop Layout Paint Mixing Line Service Technical Services

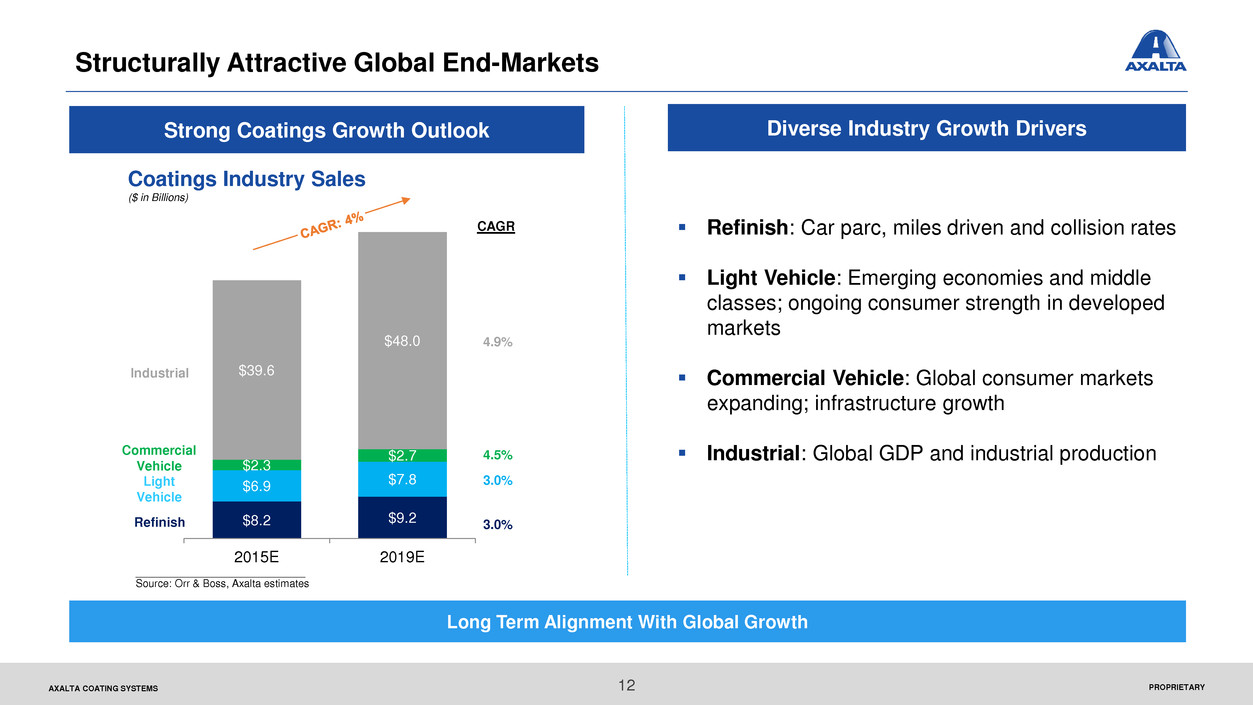

PROPRIETARY AXALTA COATING SYSTEMS 12 Structurally Attractive Global End-Markets Strong Coatings Growth Outlook Long Term Alignment With Global Growth Refinish: Car parc, miles driven and collision rates Light Vehicle: Emerging economies and middle classes; ongoing consumer strength in developed markets Commercial Vehicle: Global consumer markets expanding; infrastructure growth Industrial: Global GDP and industrial production Diverse Industry Growth Drivers Commercial Vehicle Light Vehicle Refinish Industrial 4.9% 4.5% 3.0% 3.0% CAGR Coatings Industry Sales ($ in Billions) _____________________________ Source: Orr & Boss, Axalta estimates $8.2 $9.2 $6.9 $7.8 $2.3 $2.7 $39.6 $48.0 2015E 2019E

PROPRIETARY AXALTA COATING SYSTEMS 13 Highly Variable Cost Structure And Low Capital Intensity ~50% of COGS come from variable raw material inputs Utilize temporary labor to enable wage structure flexibility Toggle other costs as needed in a downturn, including both variable and semi-fixed Low Capital Intensity Capex at $150 million is 3.7% of sales, but only 1.4% for maintenance capex Batch production process is inherently flexible Capacity additions are very modular to minimize stranded cost impacts Variable Cost Structure Well Positioned to React to Cyclical Downturns

PROPRIETARY AXALTA COATING SYSTEMS Axalta’s Future State: A Global, High-Performing, Coatings Leader Consistent Growth Margin Expansion Effective Capital Allocation Enhanced Shareholder Returns Axalta’s Vision To maximize our customers’ productivity and product functionality by offering them innovative coatings solutions and best-of-class service 14

PROPRIETARY AXALTA COATING SYSTEMS 15 Axalta Aims To Grow The Business While Refining The Cost Structure Visible Growth Supported by Clear Strategies & Enhanced Resources Focus on Emerging Markets for Long Term Opportunity Globalizing Existing Products to Reach Underserved Markets Optimizing Procurement Focus on Operating Excellence Streamlining Operations Enhancing Productivity Sa le s G ro w th Strateg ie s Co s t Redu c tion In itiat iv e s Profitable Growth Underpinned by Both Top and Bottom Line Initiatives

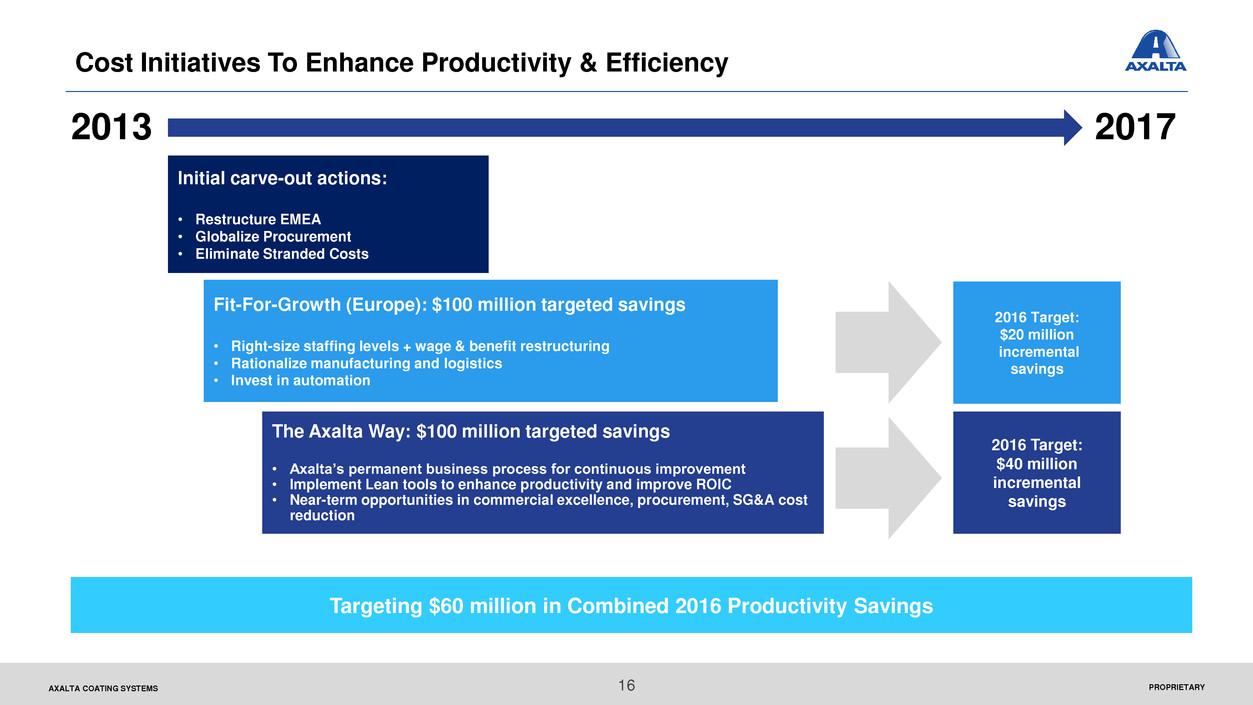

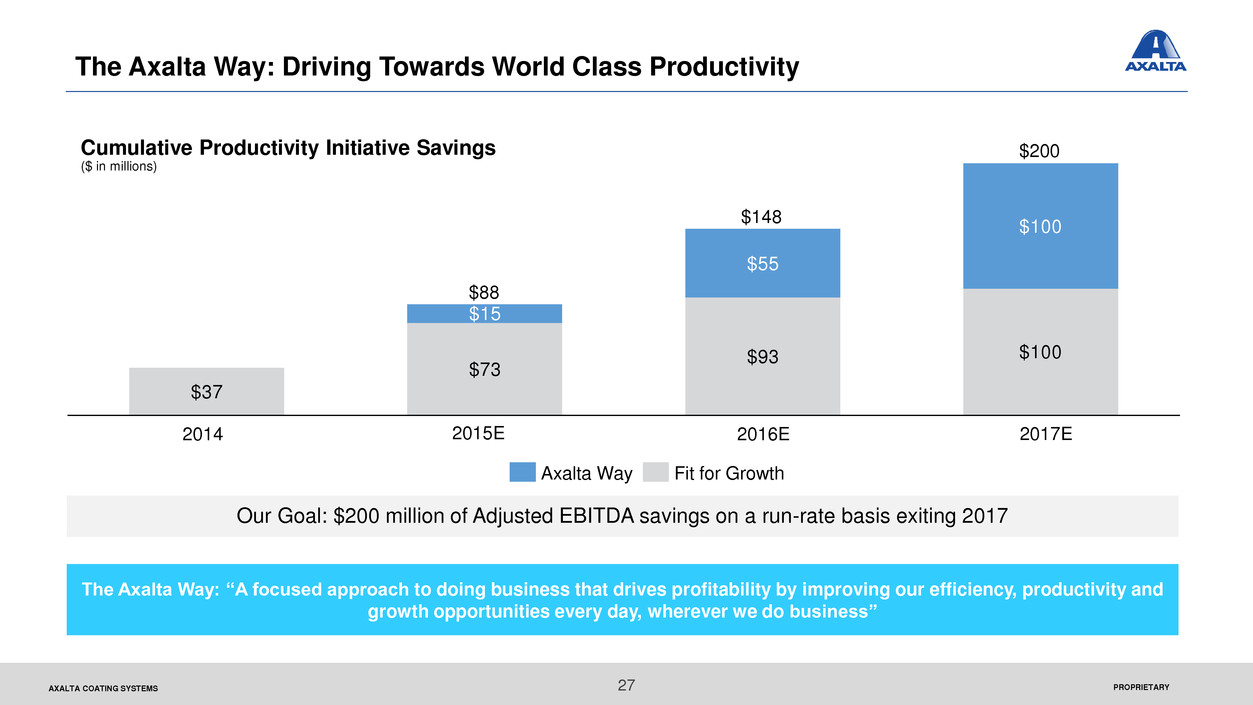

PROPRIETARY AXALTA COATING SYSTEMS 16 Cost Initiatives To Enhance Productivity & Efficiency Fit-For-Growth (Europe): $100 million targeted savings • Right-size staffing levels + wage & benefit restructuring • Rationalize manufacturing and logistics • Invest in automation Initial carve-out actions: • Restructure EMEA • Globalize Procurement • Eliminate Stranded Costs The Axalta Way: $100 million targeted savings • Axalta’s permanent business process for continuous improvement • Implement Lean tools to enhance productivity and improve ROIC • Near-term opportunities in commercial excellence, procurement, SG&A cost reduction 2013 2017 2016 Target: $40 million incremental savings 2016 Target: $20 million incremental savings Targeting $60 million in Combined 2016 Productivity Savings

PROPRIETARY AXALTA COATING SYSTEMS 17 Axalta’s Evolution Is Grounded In Fundamental Goals Leverage our culture of accountability and focus on operational excellence Axalta’s Strategy Grow in targeted industrial coatings segments via organic growth and selective acquisitions Move into attractive adjacencies by leveraging our global technology, process and service capabilities Grow with our market-leading products and services in existing markets

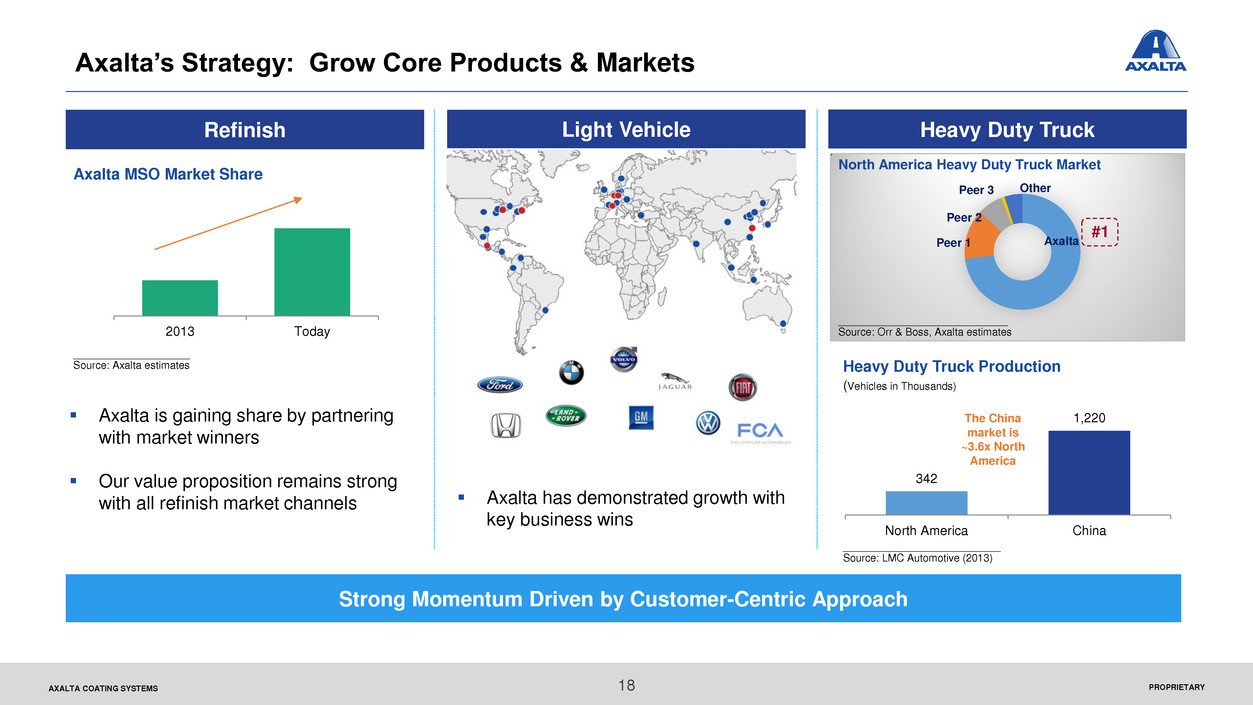

PROPRIETARY AXALTA COATING SYSTEMS 18 Axalta’s Strategy: Grow Core Products & Markets Refinish ____________________ Source: Axalta estimates Strong Momentum Driven by Customer-Centric Approach Axalta MSO Market Share 2013 Today Light Vehicle Axalta is gaining share by partnering with market winners Our value proposition remains strong with all refinish market channels Heavy Duty Truck Axalta Peer 1 Peer 2 Peer 3 Other #1 North America Heavy Duty Truck Market (Vehicles in Thousands) Heavy Duty Truck Production 342 1,220 North America China The China market is ~3.6x North America _____________________________ Source: Orr & Boss, Axalta estimates ___________________________ Source: LMC Automotive (2013) Axalta has demonstrated growth with key business wins

PROPRIETARY AXALTA COATING SYSTEMS $14.3 $15.6 $17.1 $18.5 $20.1 2014E 2015E 2016E 2017E 2018E Emerging Markets, 31% 19 Axalta’s Strategy: Accelerate Growth In Emerging Markets China Example Light Vehicles, Per 1,000 People China Car Parc (thousands) 743 263 230 129 61 19 United States Central & Eastern Europe Mexico Brazil China India Damaged Vehicles Per 1M km Driven (2011) Axalta 2015E Net Sales Emerging Market Growth Coatings Market ($ Billions) Significant Emerging Markets Growth Opportunity Significant Opportunity Rapid growth of middle-classes in emerging economies Increased vehicle penetration per capita Expansion of car parc Elevated collision rates vs. developed markets United States Brazil China___________________________ Source: Orr & Boss (2014) _________________________________________ Source: LMC Automotive (2013), World Bank (2013) ____________________ Source: Axalta estimates ___________________________ Source: LMC Automotive (2013) 50 62 77 93 110 129 149 170 193 217 2008A 2011A 2014E 2017E

PROPRIETARY AXALTA COATING SYSTEMS Architectural 20 Axalta’s Strategy: Targeted Industrial Coatings Expansion Growth from Leveraging Our Product Portfolio in Underserved Markets Strong product portfolio in powder, liquid, and e-coat Implemented global end-market business structure to capitalize on opportunities Leveraging existing technology and enhanced sales organization to grow A Broad Industrial Portfolio Electrical Insulation Agricultural, Construction, & Earthmoving Equipment (ACE) Oil & Gas

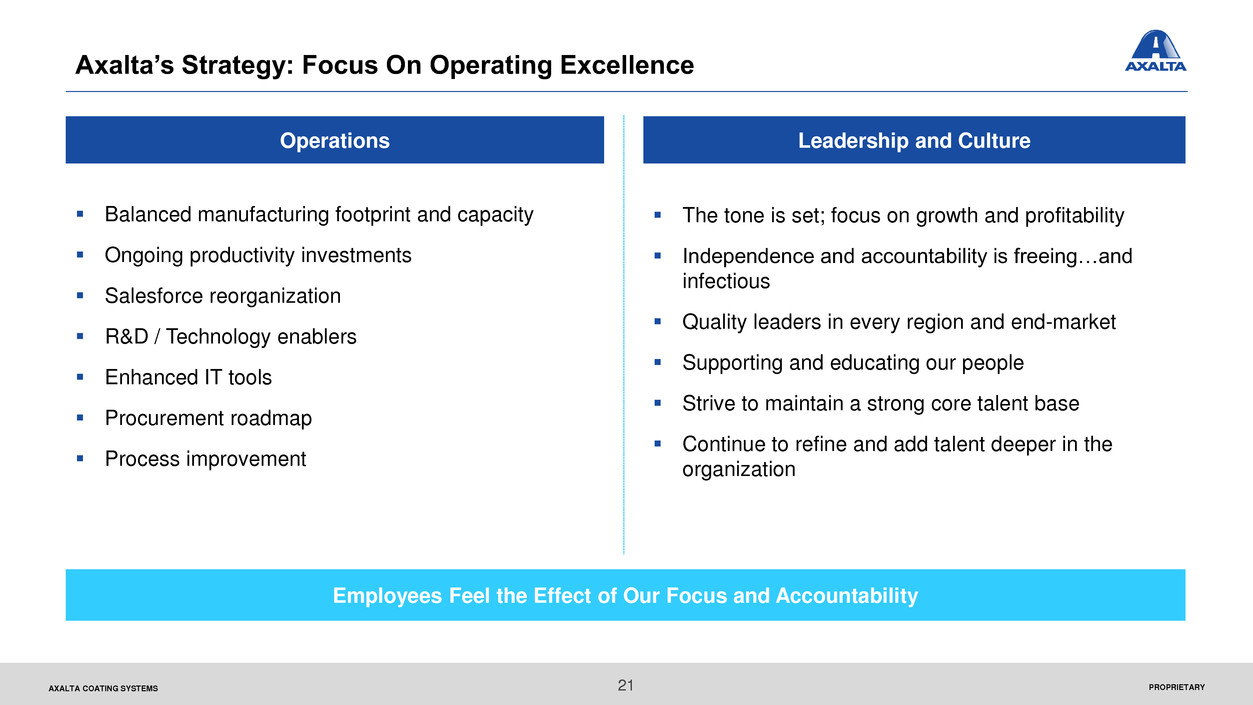

PROPRIETARY AXALTA COATING SYSTEMS Axalta’s Strategy: Focus On Operating Excellence Balanced manufacturing footprint and capacity Ongoing productivity investments Salesforce reorganization R&D / Technology enablers Enhanced IT tools Procurement roadmap Process improvement Leadership and Culture The tone is set; focus on growth and profitability Independence and accountability is freeing…and infectious Quality leaders in every region and end-market Supporting and educating our people Strive to maintain a strong core talent base Continue to refine and add talent deeper in the organization Operations Employees Feel the Effect of Our Focus and Accountability 21

Financial Overview Robert Bryant EVP & CFO

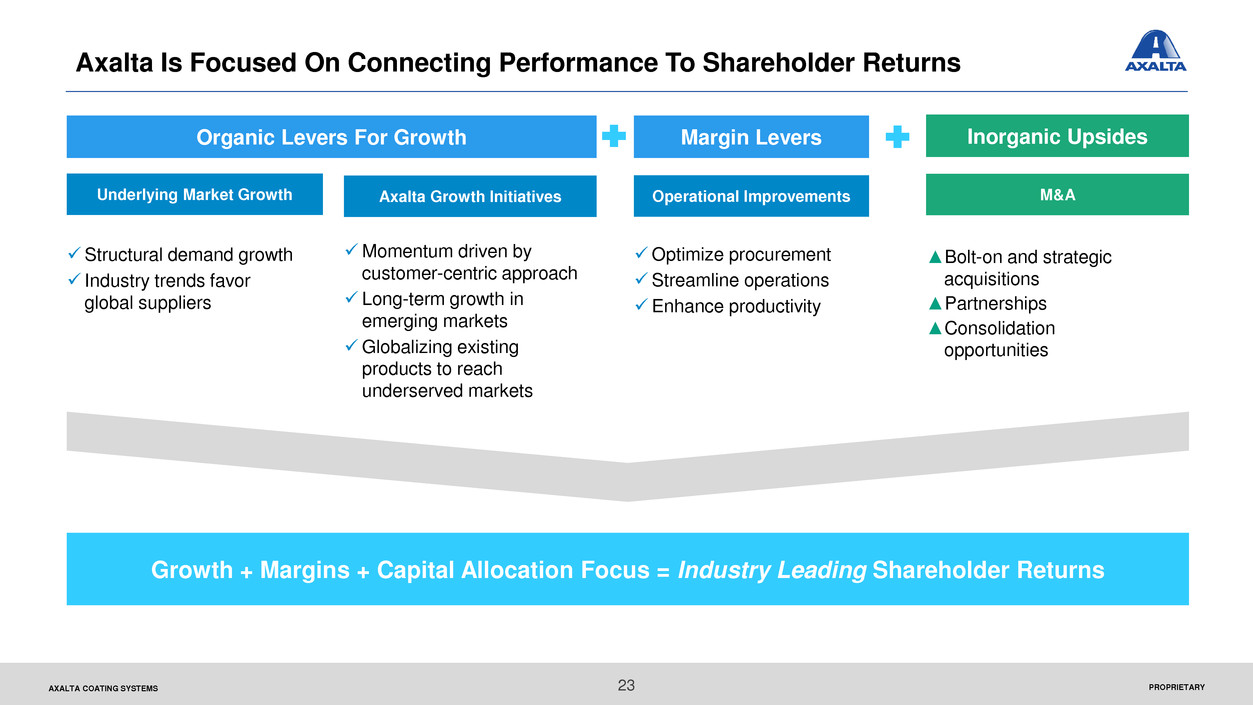

PROPRIETARY AXALTA COATING SYSTEMS 23 Axalta Is Focused On Connecting Performance To Shareholder Returns Underlying Market Growth Axalta Growth Initiatives Operational Improvements M&A Structural demand growth Industry trends favor global suppliers Momentum driven by customer-centric approach Long-term growth in emerging markets Globalizing existing products to reach underserved markets Optimize procurement Streamline operations Enhance productivity ▲Bolt-on and strategic acquisitions ▲Partnerships ▲Consolidation opportunities Organic Levers For Growth Inorganic Upsides Margin Levers Growth + Margins + Capital Allocation Focus = Industry Leading Shareholder Returns

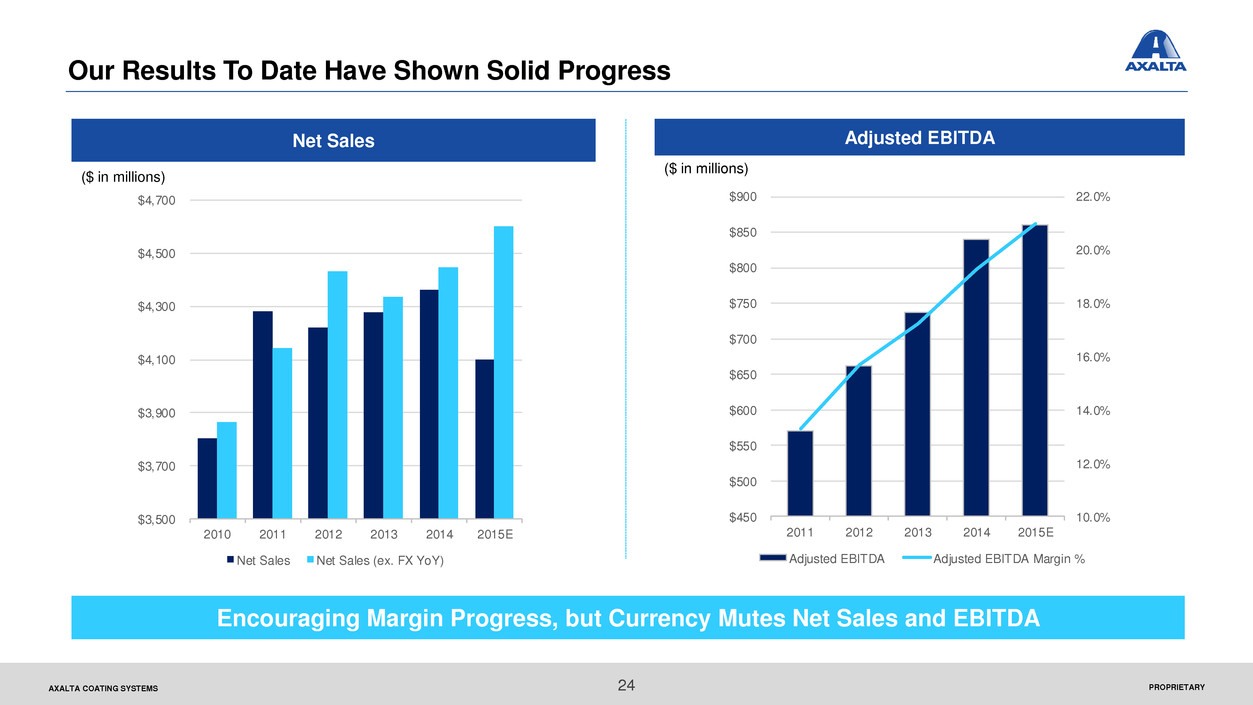

PROPRIETARY AXALTA COATING SYSTEMS Our Results To Date Have Shown Solid Progress Encouraging Margin Progress, but Currency Mutes Net Sales and EBITDA Net Sales Adjusted EBITDA ($ in millions) ($ in millions) 24 $3,500 $3,700 $3,900 $4,100 $4,300 $4,500 $4,700 2010 2011 2012 2013 2014 2015E Net Sales Net Sales (ex. FX YoY) 10.0% 12.0% 14.0% 16.0% 18.0% 20.0% 22.0% $450 $500 $550 $600 $650 $700 $750 $800 $850 $900 011 2012 2013 2014 2015E Adju ted EBITDA Adjusted EBITDA Margin %

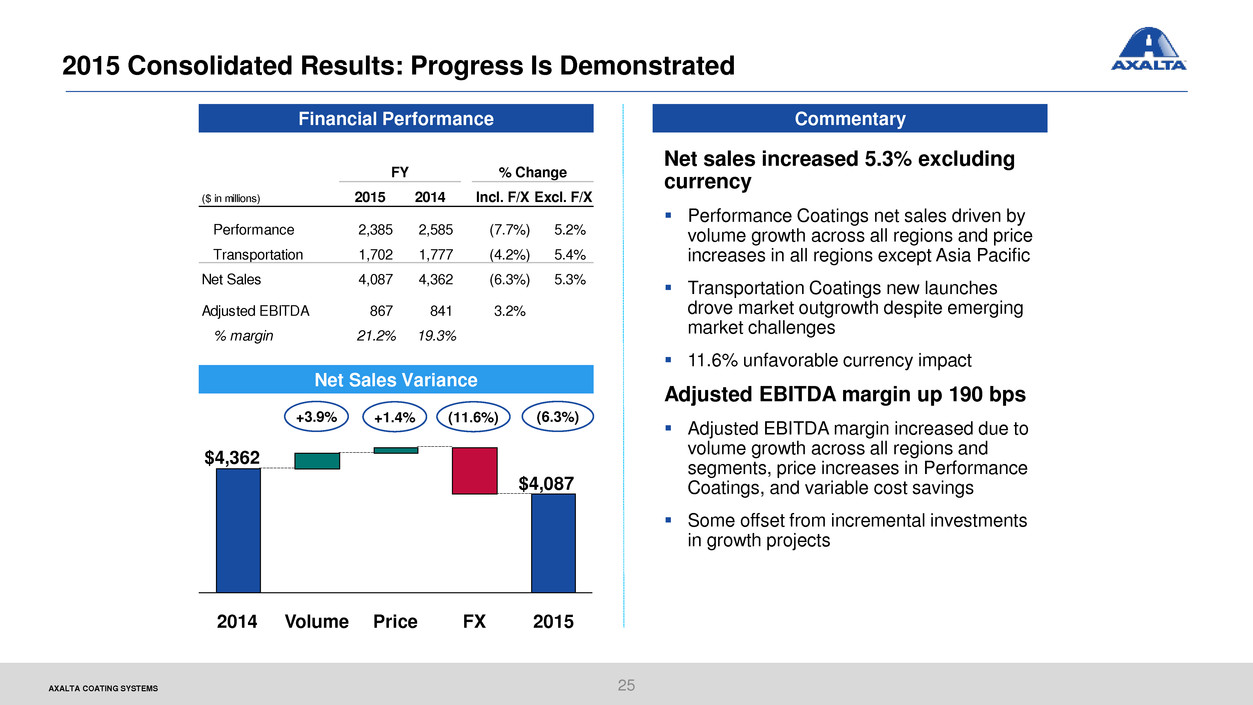

AXALTA COATING SYSTEMS 25 2015 Consolidated Results: Progress Is Demonstrated Financial Performance Commentary Net Sales Variance +3.9% +1.4% (11.6%) (6.3%) $4,087 $4,362 2015 FX Volume Price 2014 Net sales increased 5.3% excluding currency Performance Coatings net sales driven by volume growth across all regions and price increases in all regions except Asia Pacific Transportation Coatings new launches drove market outgrowth despite emerging market challenges 11.6% unfavorable currency impact Adjusted EBITDA margin up 190 bps Adjusted EBITDA margin increased due to volume growth across all regions and segments, price increases in Performance Coatings, and variable cost savings Some offset from incremental investments in growth projects ($ in millions) 2015 2014 Incl. F/X Excl. F/X Performance 2,385 2,585 (7.7%) 5.2% Transportation 1,702 1,777 (4.2%) 5.4% Net Sales 4,087 4,362 (6.3%) 5.3% Adjusted EBITDA 867 841 3.2% % margin 21.2% 19.3% FY % Change

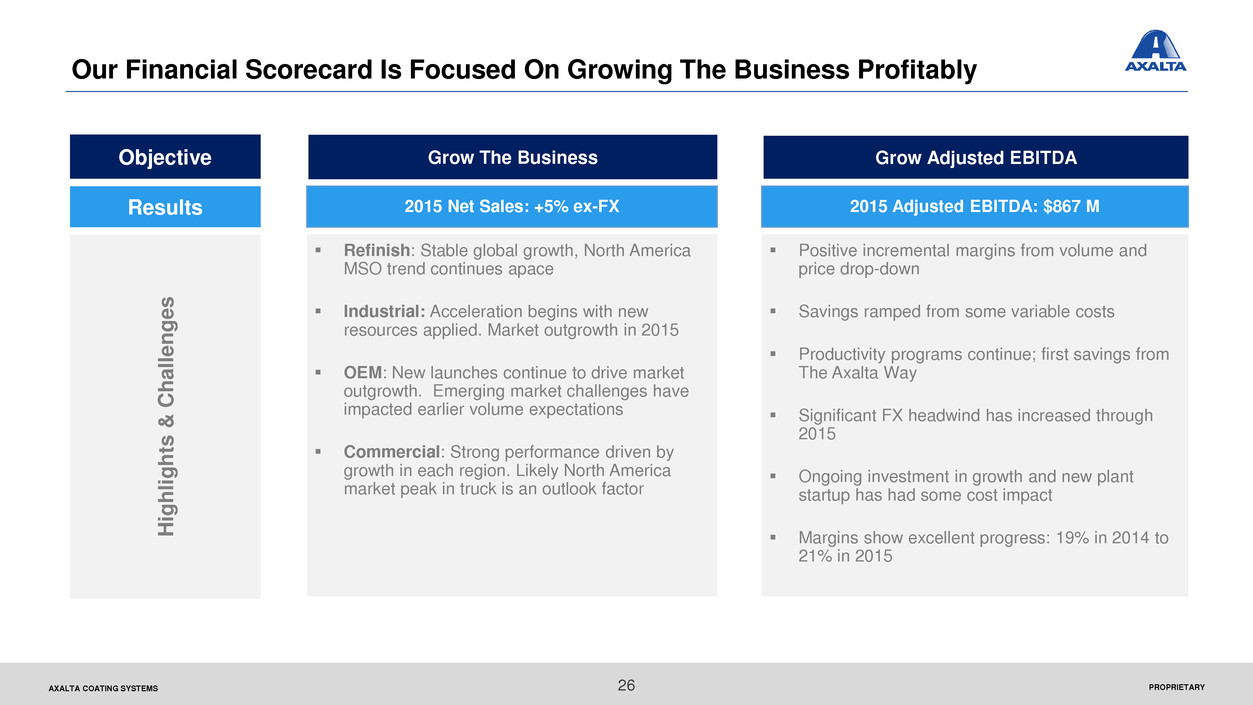

PROPRIETARY AXALTA COATING SYSTEMS 26 Our Financial Scorecard Is Focused On Growing The Business Profitably Grow The Business Grow Adjusted EBITDA 2015 Net Sales: +5% ex-FX Refinish: Stable global growth, North America MSO trend continues apace Industrial: Acceleration begins with new resources applied. Market outgrowth in 2015 OEM: New launches continue to drive market outgrowth. Emerging market challenges have impacted earlier volume expectations Commercial: Strong performance driven by growth in each region. Likely North America market peak in truck is an outlook factor 2015 Adjusted EBITDA: $867 M Positive incremental margins from volume and price drop-down Savings ramped from some variable costs Productivity programs continue; first savings from The Axalta Way Significant FX headwind has increased through 2015 Ongoing investment in growth and new plant startup has had some cost impact Margins show excellent progress: 19% in 2014 to 21% in 2015 Objective Results Highlights & Ch a lleng e s

PROPRIETARY AXALTA COATING SYSTEMS The Axalta Way: Driving Towards World Class Productivity Our Goal: $200 million of Adjusted EBITDA savings on a run-rate basis exiting 2017 Cumulative Productivity Initiative Savings ($ in millions) The Axalta Way: “A focused approach to doing business that drives profitability by improving our efficiency, productivity and growth opportunities every day, wherever we do business” 27 2017E 2015E 2016E 2014 Fit for Growth Axalta Way $37 $73 $93 $100 $55 $100 $15 $88 $200 $148

PROPRIETARY AXALTA COATING SYSTEMS 28 Our Financial Guiding Principles Managing the Capital: Capex Prioritization Metrics-Based Management: Driving the Business with Data Capital Allocation: Improved ROIC Financial Optimization

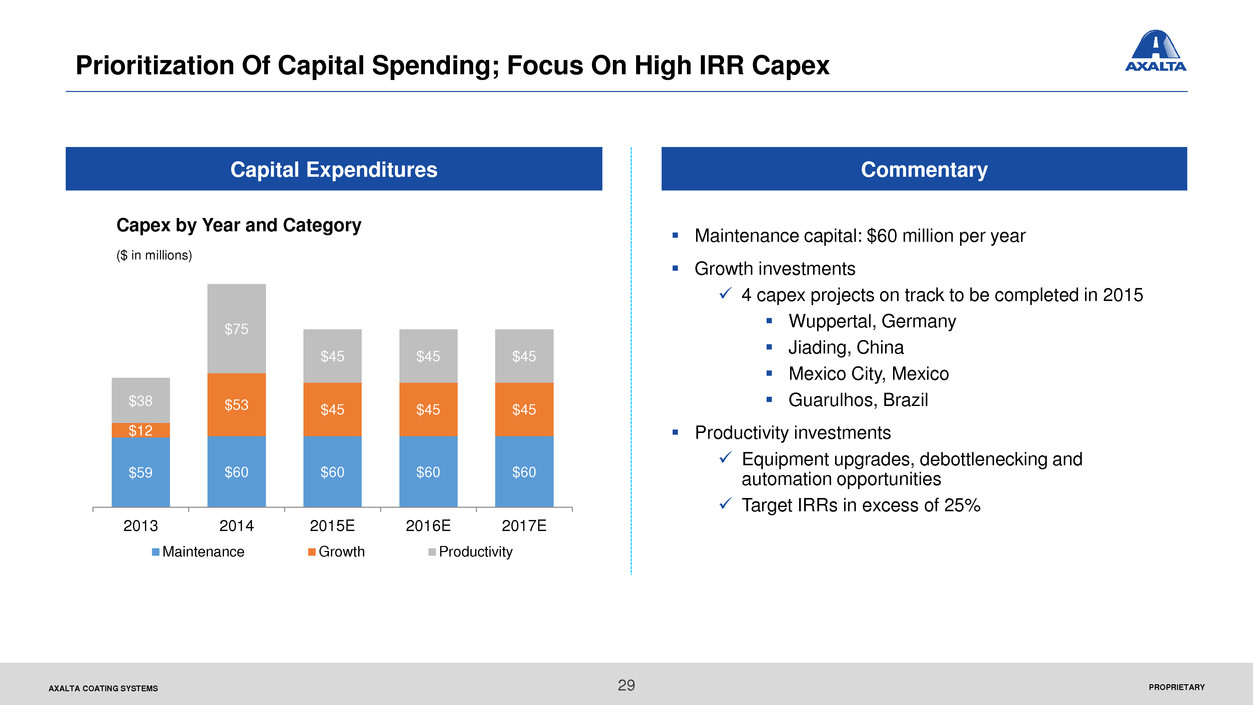

PROPRIETARY AXALTA COATING SYSTEMS Prioritization Of Capital Spending; Focus On High IRR Capex Maintenance capital: $60 million per year Growth investments 4 capex projects on track to be completed in 2015 Wuppertal, Germany Jiading, China Mexico City, Mexico Guarulhos, Brazil Productivity investments Equipment upgrades, debottlenecking and automation opportunities Target IRRs in excess of 25% Capital Expenditures Capex by Year and Category ($ in millions) Commentary 29 $59 $60 $60 $60 $60 $12 $53 $45 $45 $45 $38 $75 $45 $45 $45 2013 2014 2015E 2016E 2017E Maintenance Growth Productivity

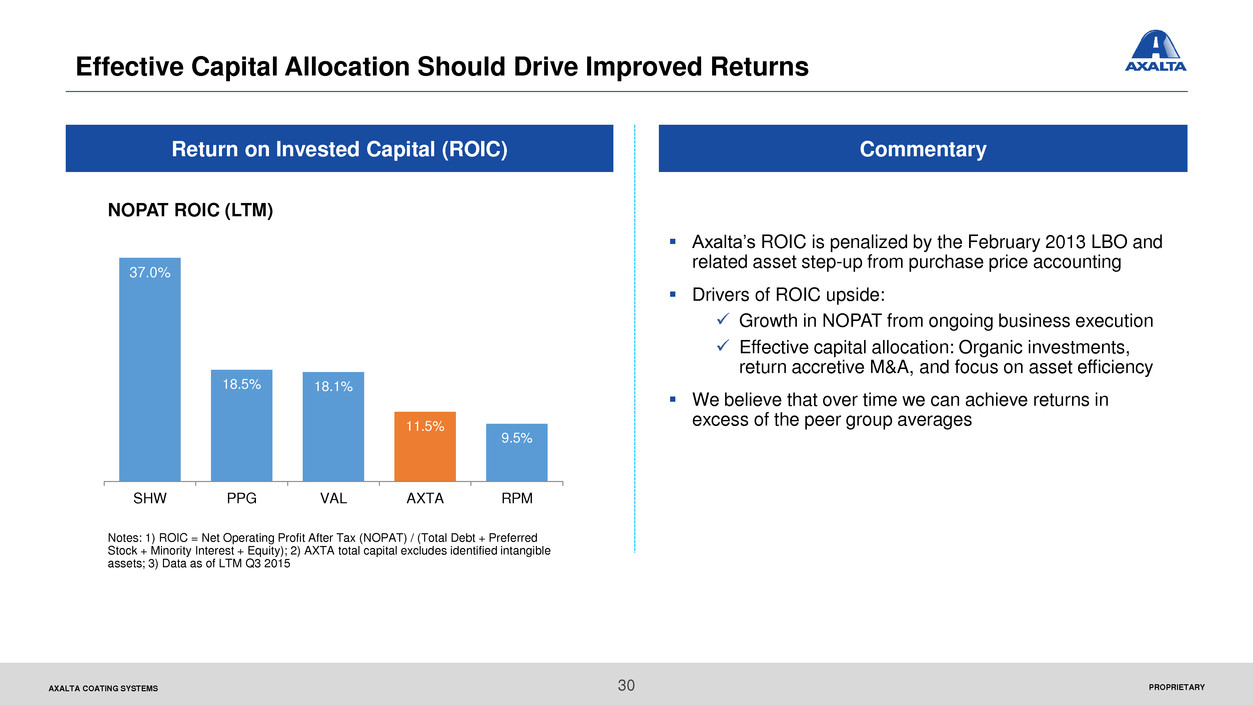

PROPRIETARY AXALTA COATING SYSTEMS Effective Capital Allocation Should Drive Improved Returns Notes: 1) ROIC = Net Operating Profit After Tax (NOPAT) / (Total Debt + Preferred Stock + Minority Interest + Equity); 2) AXTA total capital excludes identified intangible assets; 3) Data as of LTM Q3 2015 Axalta’s ROIC is penalized by the February 2013 LBO and related asset step-up from purchase price accounting Drivers of ROIC upside: Growth in NOPAT from ongoing business execution Effective capital allocation: Organic investments, return accretive M&A, and focus on asset efficiency We believe that over time we can achieve returns in excess of the peer group averages Return on Invested Capital (ROIC) Commentary NOPAT ROIC (LTM) 30 37.0% 18.5% 18.1% 11.5% 9.5% SHW PPG VAL AXTA RPM

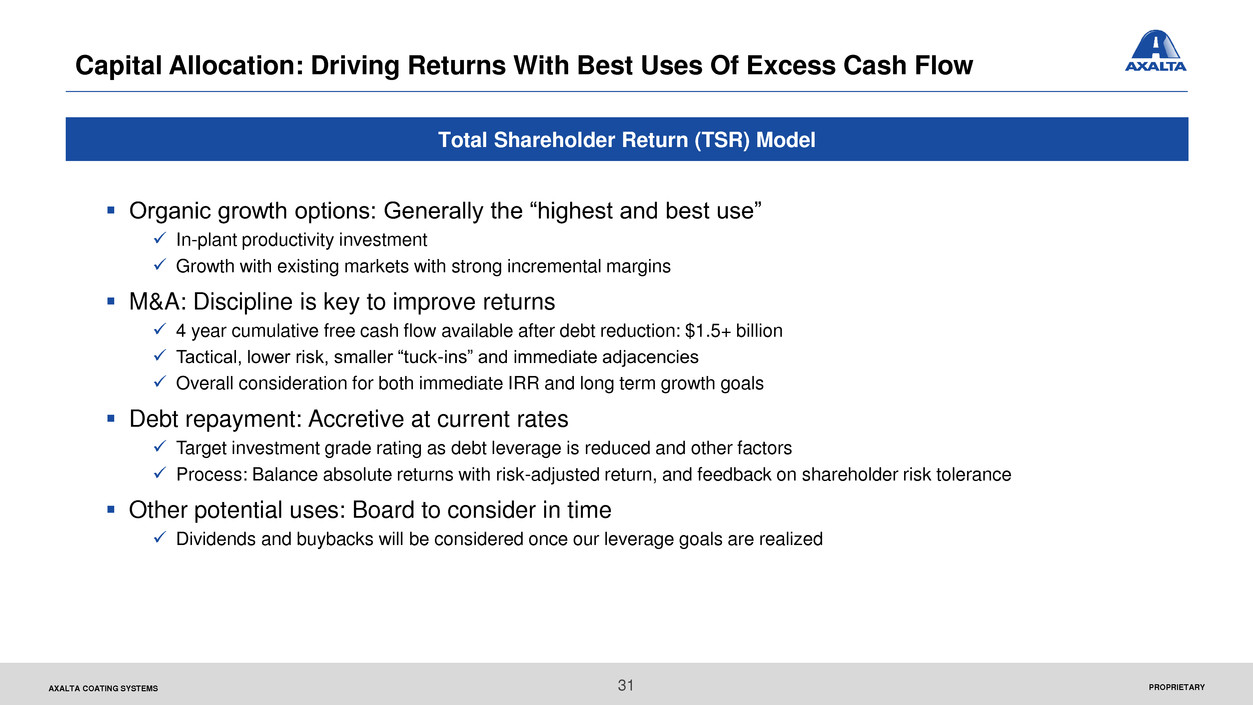

PROPRIETARY AXALTA COATING SYSTEMS Capital Allocation: Driving Returns With Best Uses Of Excess Cash Flow Organic growth options: Generally the “highest and best use” In-plant productivity investment Growth with existing markets with strong incremental margins M&A: Discipline is key to improve returns 4 year cumulative free cash flow available after debt reduction: $1.5+ billion Tactical, lower risk, smaller “tuck-ins” and immediate adjacencies Overall consideration for both immediate IRR and long term growth goals Debt repayment: Accretive at current rates Target investment grade rating as debt leverage is reduced and other factors Process: Balance absolute returns with risk-adjusted return, and feedback on shareholder risk tolerance Other potential uses: Board to consider in time Dividends and buybacks will be considered once our leverage goals are realized Total Shareholder Return (TSR) Model 31

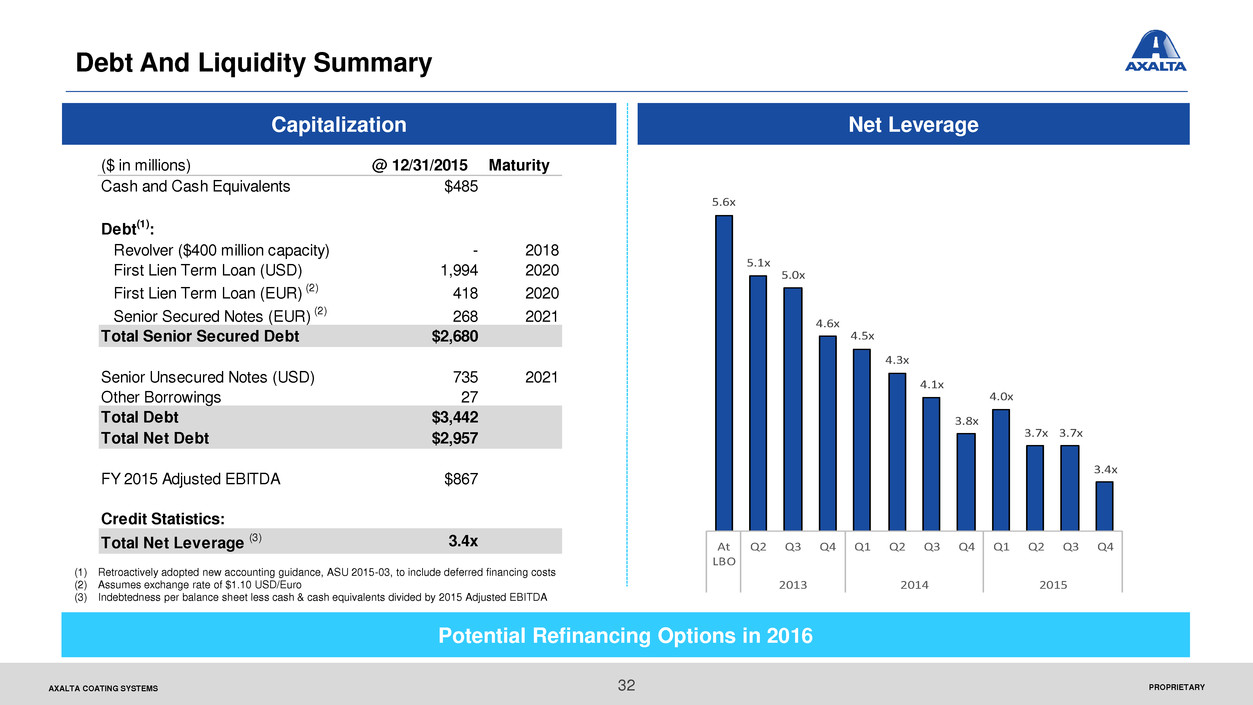

PROPRIETARY AXALTA COATING SYSTEMS Capitalization 32 Debt And Liquidity Summary (1) Retroactively adopted new accounting guidance, ASU 2015-03, to include deferred financing costs (2) Assumes exchange rate of $1.10 USD/Euro (3) Indebtedness per balance sheet less cash & cash equivalents divided by 2015 Adjusted EBITDA Net Leverage Potential Refinancing Options in 2016 ($ in millions) @ 12/31/2015 Maturity Cash and Cash Equivalents $485 Debt(1): Revolver ($400 million capacity) - 2018 First Lien Term Loan (USD) 1,994 2020 First Lien Term Loan (EUR) (2) 418 2020 Senior Secured Notes (EUR) (2) 268 2021 Total Senior Secured Debt $2,680 Senior Unsecured Notes (USD) 735 2021 Other Borrowings 27 Total Debt $3,442 Total Net Debt $2,957 FY 2015 Adjusted EBITDA $867 Credit Statistics: Total Net Leverage (3) 3.4x 5.6x 5.1x 5.0x 4.6x 4.5x 4.3x 4.1x 3.8x 4.0x 3.7x 3.7x 3.4x At LBO Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 2013 2014 2015

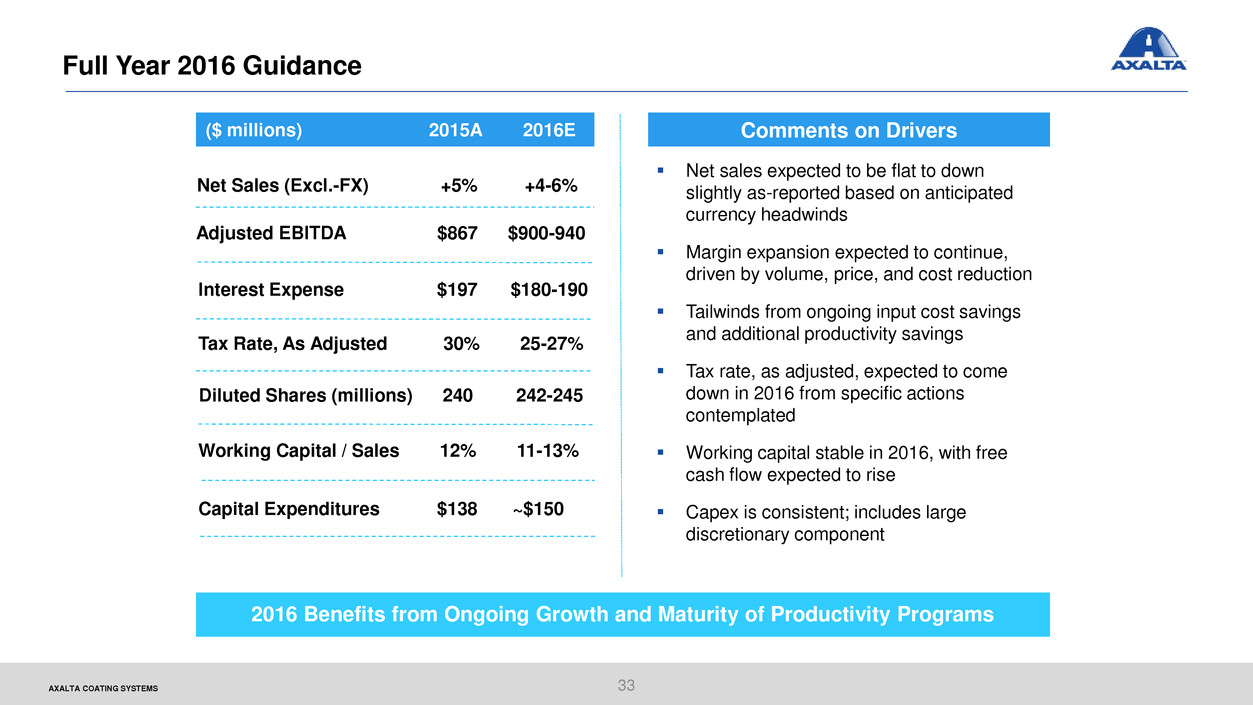

AXALTA COATING SYSTEMS Full Year 2016 Guidance 33 2016 Benefits from Ongoing Growth and Maturity of Productivity Programs Net sales expected to be flat to down slightly as-reported based on anticipated currency headwinds Margin expansion expected to continue, driven by volume, price, and cost reduction Tailwinds from ongoing input cost savings and additional productivity savings Tax rate, as adjusted, expected to come down in 2016 from specific actions contemplated Working capital stable in 2016, with free cash flow expected to rise Capex is consistent; includes large discretionary component ($ millions) 2015A 2016E Net Sales (Excl.-FX) +5% +4-6% Working Capital / Sales 12% 11-13% Tax Rate, As Adjusted 30% 25-27% Diluted Shares (millions) 240 242-245 Comments on Drivers Capital Expenditures $138 ~$150 Interest Expense $197 $180-190 Adjusted EBITDA $867 $900-940

Performance Coatings: Refinish Nigel Budden VP, Global Customer Excellence

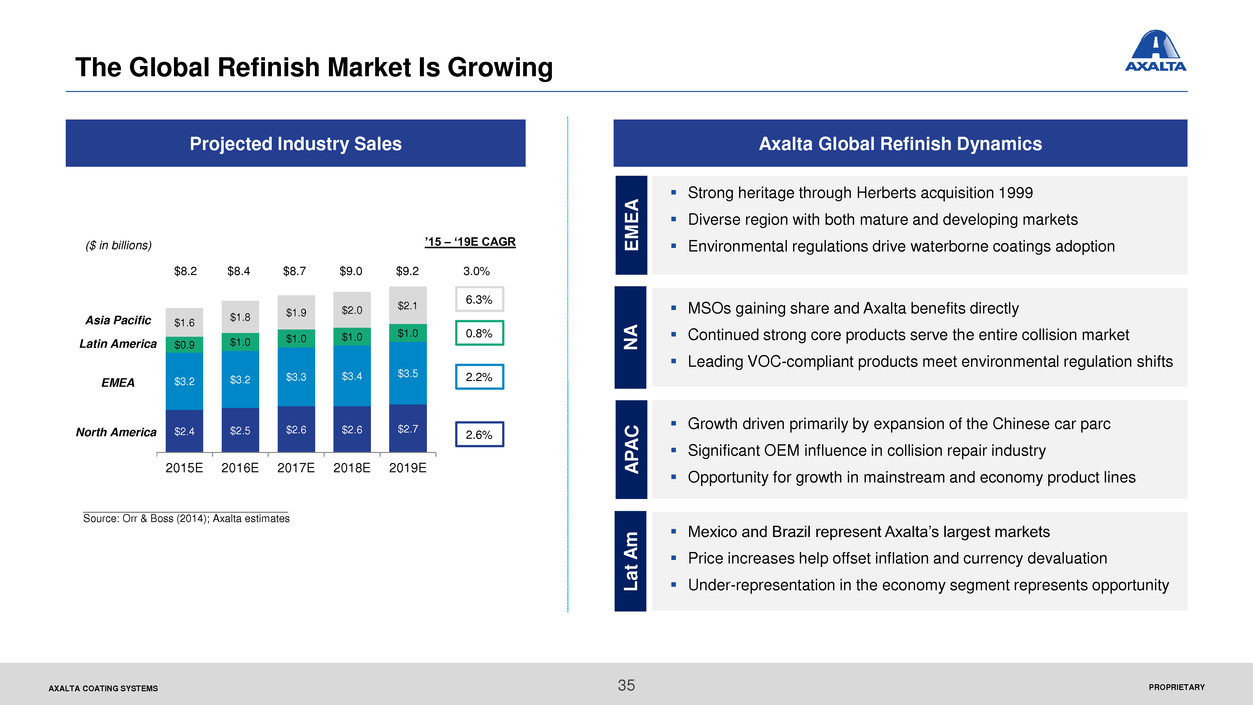

PROPRIETARY AXALTA COATING SYSTEMS The Global Refinish Market Is Growing Projected Industry Sales ($ in billions) Asia Pacific EMEA North America 6.3% 0.8% 2.2% 2.6% $2.4 $2.5 $2.6 $2.6 $2.7 $3.2 $3.2 $3.3 $3.4 $3.5 $0.9 $1.0 $1.0 $1.0 $1.0 $1.6 $1.8 $1.9 $2.0 $2.1 2015E 2016E 2017E 2018E 2019E ’15 – ‘19E CAGR ___________________________________ Source: Orr & Boss (2014); Axalta estimates Latin America $8.2 $8.4 $8.7 $9.0 $9.2 3.0% Axalta Global Refinish Dynamics Strong heritage through Herberts acquisition 1999 Diverse region with both mature and developing markets Environmental regulations drive waterborne coatings adoption MSOs gaining share and Axalta benefits directly Continued strong core products serve the entire collision market Leading VOC-compliant products meet environmental regulation shifts Growth driven primarily by expansion of the Chinese car parc Significant OEM influence in collision repair industry Opportunity for growth in mainstream and economy product lines Mexico and Brazil represent Axalta’s largest markets Price increases help offset inflation and currency devaluation Under-representation in the economy segment represents opportunity E M E A N A A P A C La t A m 35

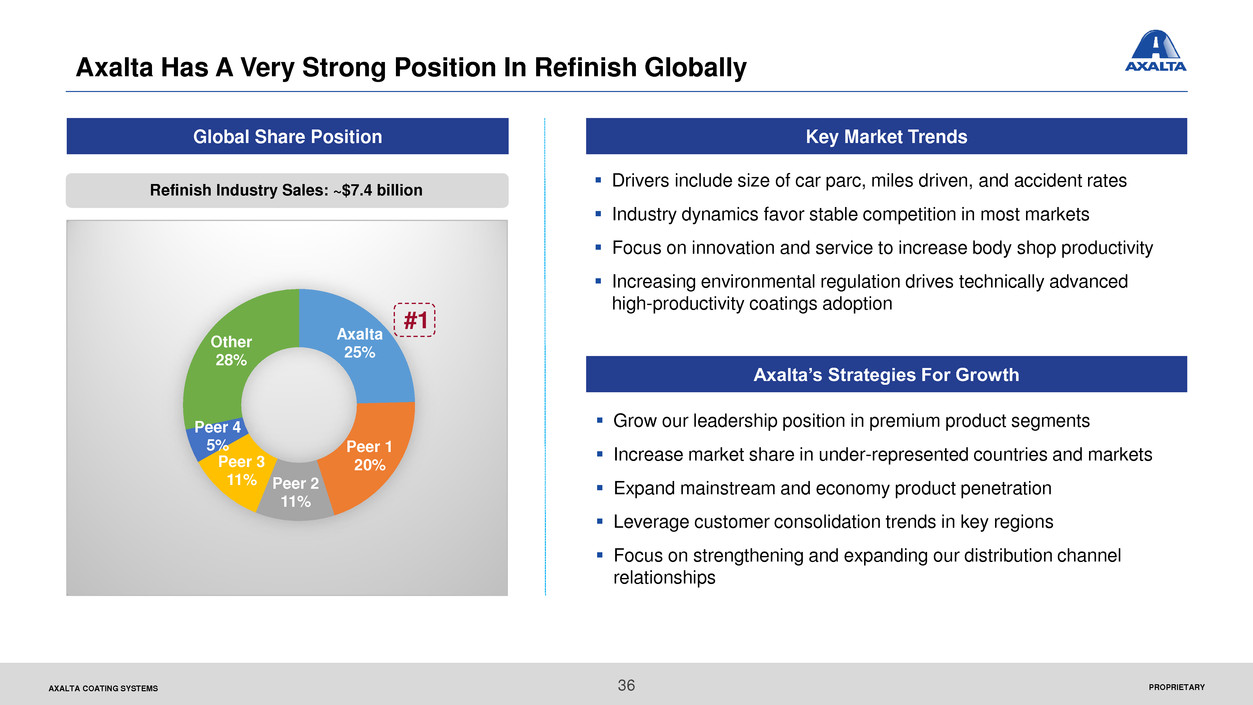

PROPRIETARY AXALTA COATING SYSTEMS Axalta Has A Very Strong Position In Refinish Globally Global Share Position Key Market Trends Axalta 25% Peer 1 20% Peer 2 11% Peer 3 11% Peer 4 5% Other 28% Refinish Industry Sales: ~$7.4 billion #1 Drivers include size of car parc, miles driven, and accident rates Industry dynamics favor stable competition in most markets Focus on innovation and service to increase body shop productivity Increasing environmental regulation drives technically advanced high-productivity coatings adoption Grow our leadership position in premium product segments Increase market share in under-represented countries and markets Expand mainstream and economy product penetration Leverage customer consolidation trends in key regions Focus on strengthening and expanding our distribution channel relationships Axalta’s Strategies For Growth 36

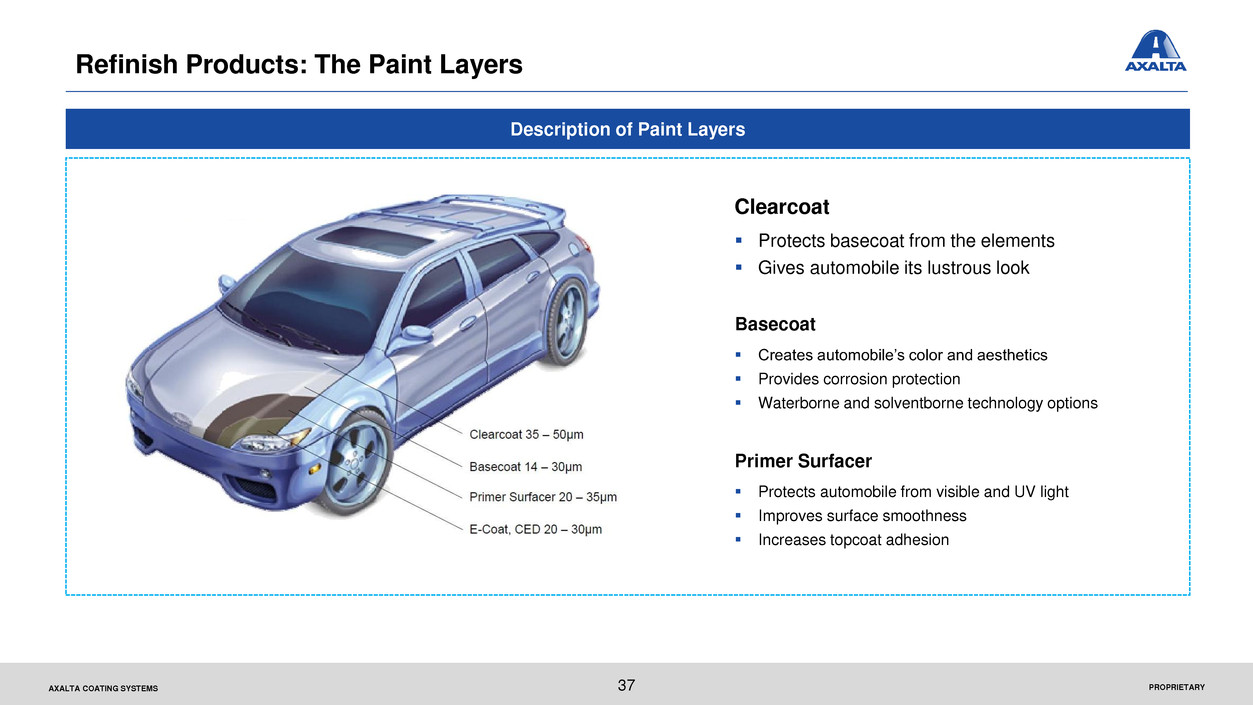

PROPRIETARY AXALTA COATING SYSTEMS 37 Refinish Products: The Paint Layers Clearcoat Protects basecoat from the elements Gives automobile its lustrous look Basecoat Creates automobile’s color and aesthetics Provides corrosion protection Waterborne and solventborne technology options Primer Surfacer Protects automobile from visible and UV light Improves surface smoothness Increases topcoat adhesion Description of Paint Layers

Performance Coatings: Industrial Coatings Michael Cash SVP, President, Industrial

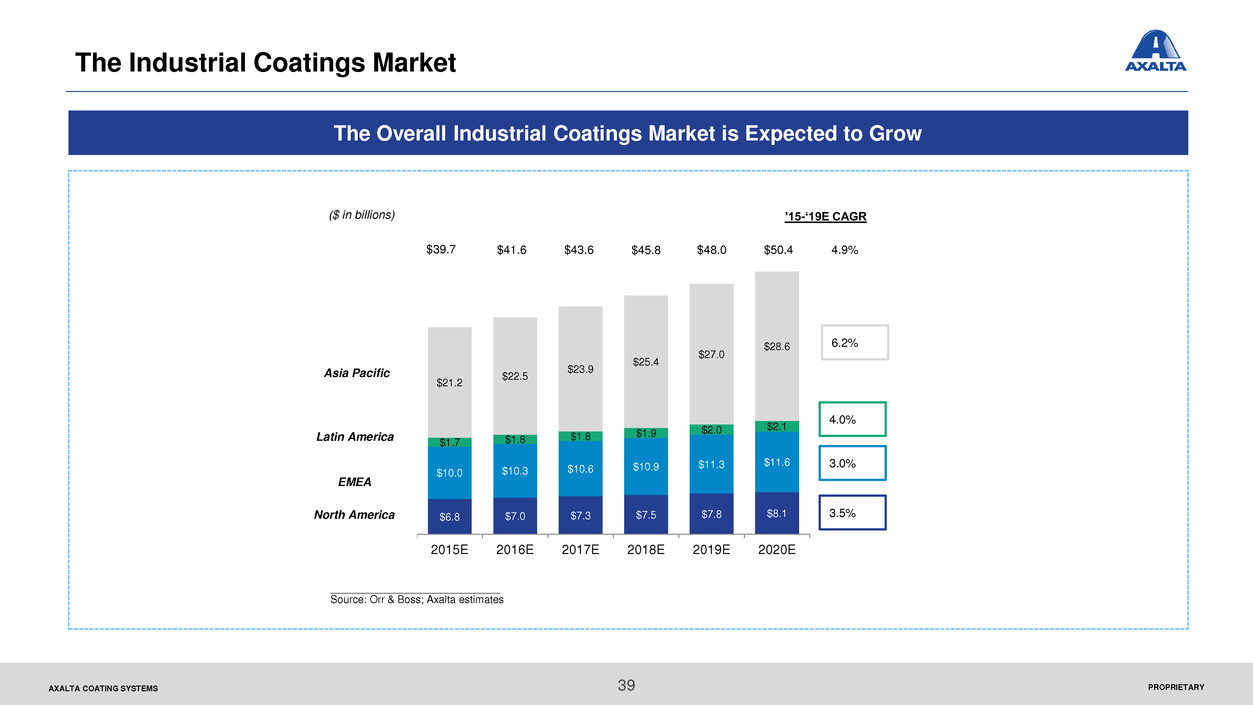

PROPRIETARY AXALTA COATING SYSTEMS ’15-‘19E CAGR ($ in billions) Asia Pacific EMEA North America 6.2% 4.0% 3.0% 3.5% 4.9% $6.8 $7.0 $7.3 $7.5 $7.8 $8.1 $10.0 $10.3 $10.6 $10.9 $11.3 $11.6 $1.7 $1.8 $1.8 $1.9 $2.0 $2.1 $21.2 $22.5 $23.9 $25.4 $27.0 $28.6 2015E 2016E 2017E 2018E 2019E 2020E $50.4 _____________________________ Source: Orr & Boss; Axalta estimates Latin America $48.0 $45.8 $43.6 $39.7 $41.6 The Overall Industrial Coatings Market is Expected to Grow The Industrial Coatings Market 39

PROPRIETARY AXALTA COATING SYSTEMS [CELLREF] [CELLREF] [CELLREF] [CELLREF] [CELLREF] [CELLREF] Industrial Coatings: A $28 B Market Opportunity For Axalta Product Examples Market Drivers General Industrial Metal furniture Appliances Shelving/ racking Electrical boxes GDP Industrial Production Electrical Insulation Electric motors Transformers Electric motor production Power transmission production Architectural Extrusions Commercial building windows and curtain walls Residential windows and doors Commercial construction ACE Construction equipment Agricultural equipment Mining equipment GDP Industrial production Oil & Gas Deep sea pipelines Oil well conveyance lines Infrastructure growth Population growth Pipeline projects Coil Commercial /residential siding Garage doors Gutters, downspouts, lighting housings Appliances GDP Construction Source: Coatings World, Axalta estimates ($ billions) 40

PROPRIETARY AXALTA COATING SYSTEMS [CATEGORY NAME] [VALUE] [CATEGORY NAME][VAL UE] [CATEGORY NAME] [VALUE] [CATEGORY NAME] [VALUE] [CATEGORY NAME] [VALUE] Net Sales by Segment Business Overview Steady volume growth driven by global GDP China growth expected to exceed 7.5% Architectural market expected to grow steadily Supplier consolidation continues Consolidation driven by expanding global players Technology innovation is our base Drivers: Environmentally sustainable products, focus on productivity, corrosion resistance and innovative and vibrant color choices Customers are globalizing Local product must meet global specifications consistently across regions Global infrastructure growth is driving demand High temperature resistance required for energy applications Demand for electrical insulation products linked to infrastructure Axalta’s Industrial Business Today 41

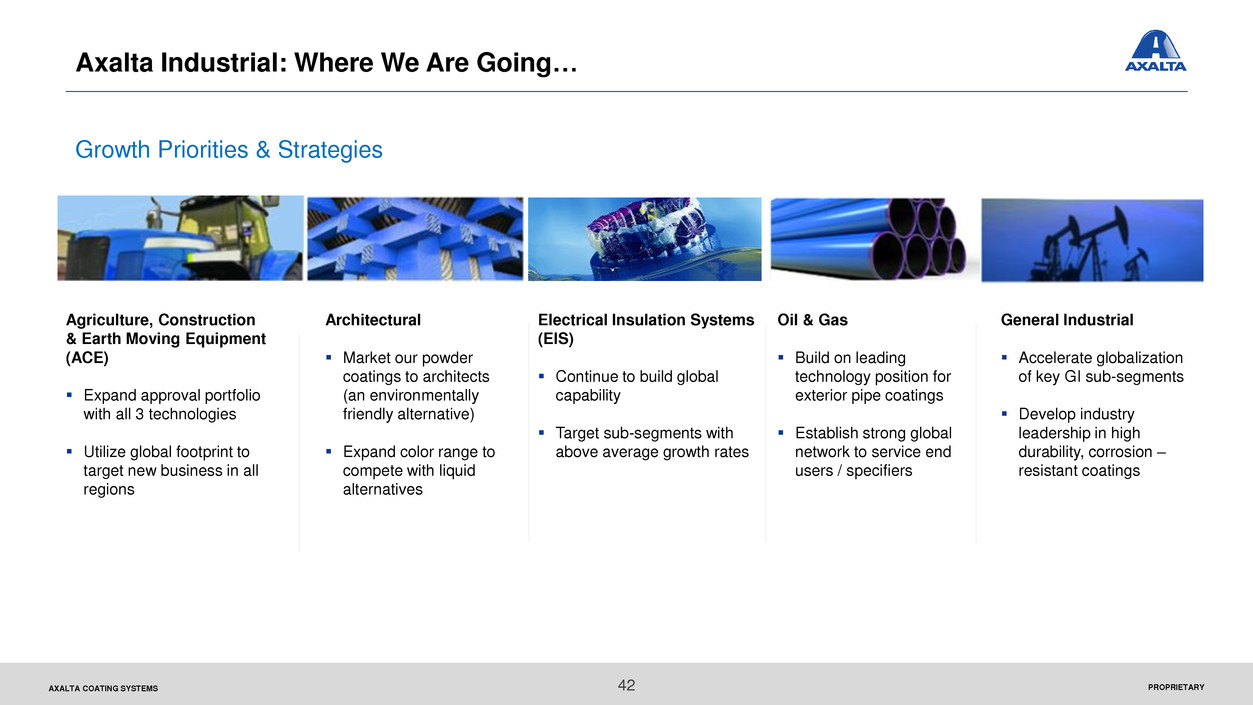

PROPRIETARY AXALTA COATING SYSTEMS Growth Priorities & Strategies Axalta Industrial: Where We Are Going… Agriculture, Construction & Earth Moving Equipment (ACE) Expand approval portfolio with all 3 technologies Utilize global footprint to target new business in all regions Architectural Market our powder coatings to architects (an environmentally friendly alternative) Expand color range to compete with liquid alternatives Electrical Insulation Systems (EIS) Continue to build global capability Target sub-segments with above average growth rates Oil & Gas Build on leading technology position for exterior pipe coatings Establish strong global network to service end users / specifiers General Industrial Accelerate globalization of key GI sub-segments Develop industry leadership in high durability, corrosion – resistant coatings 42

Transportation Coatings Overview Steven R. Markevich EVP, President Transportation Coatings and Greater China

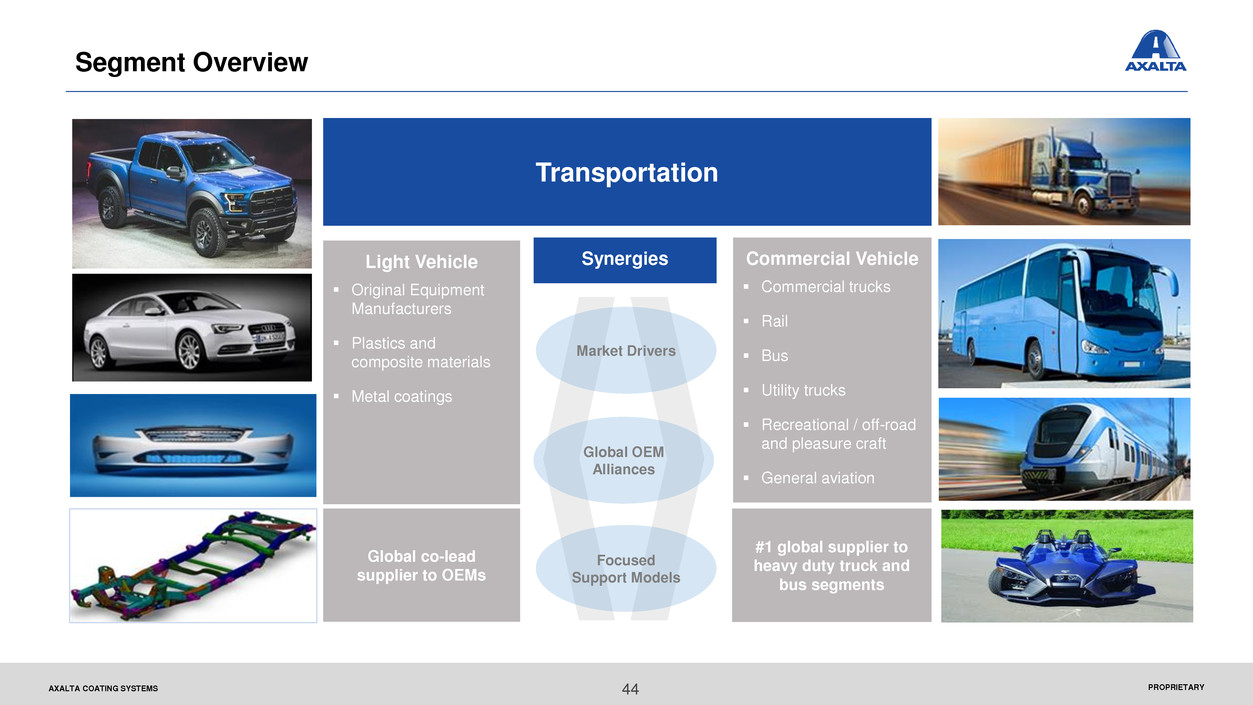

PROPRIETARY AXALTA COATING SYSTEMS Segment Overview Global co-lead supplier to OEMs Transportation Light Vehicle Original Equipment Manufacturers Plastics and composite materials Metal coatings #1 global supplier to heavy duty truck and bus segments Commercial Vehicle Commercial trucks Rail Bus Utility trucks Recreational / off-road and pleasure craft General aviation 44 Synergies Global OEM Alliances Focused Support Models Market Drivers

PROPRIETARY AXALTA COATING SYSTEMS 19% global light vehicle market share with strong OEM relationships in all regions #1 player globally in heavy duty truck and bus Extensive portfolio of technologies fit for purpose in each market Showing results to date through business wins and global launches Strong earnings contribution underscores focus on profitable growth Capacity investments to support growth in all regions Moved from regional structure to global leadership Improved alignment with strategic and underserved customers Building capability and footprint in high growth regions Expanding global brand strategy Demand drivers include Global GDP Vehicle replacement cycles Growth in emerging markets Infrastructure spending 45 Transportation Summary The global transportation market is projected to grow ~3.4% CAGR through 2019 Axalta is actively transforming its business for profitable growth Axalta is a leading global OEM coatings provider Progress to date has been strong

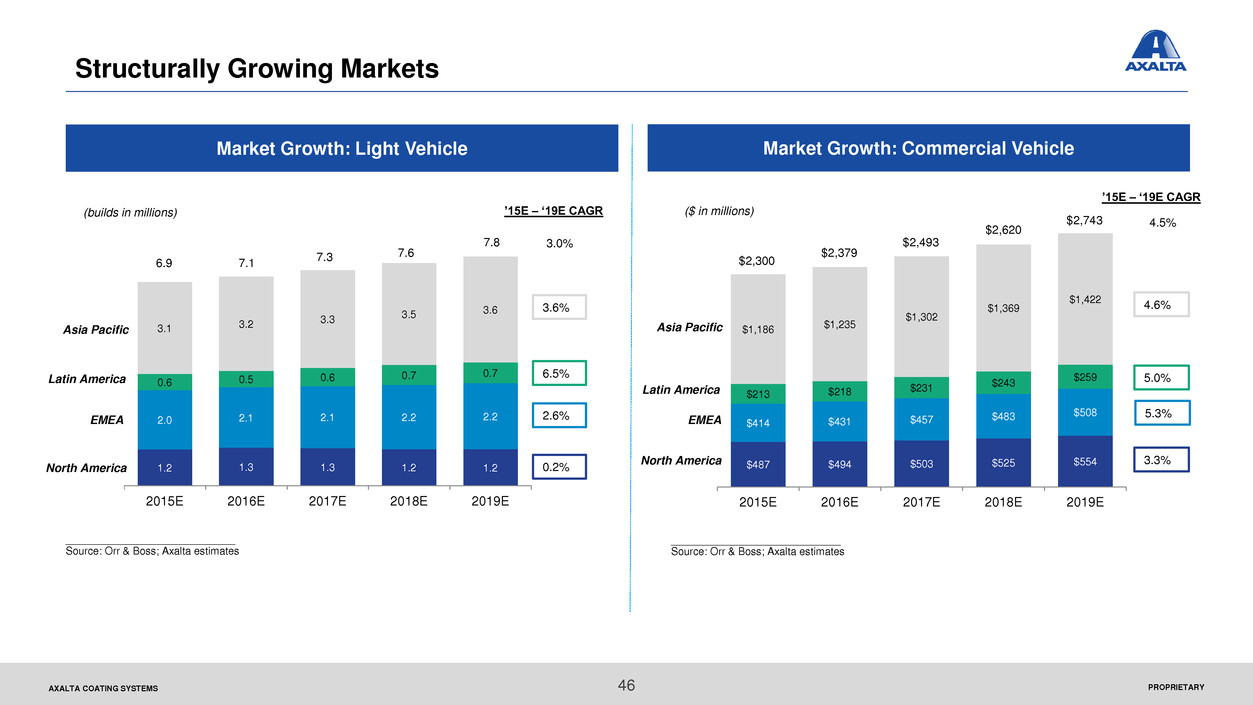

PROPRIETARY AXALTA COATING SYSTEMS Structurally Growing Markets 46 Market Growth: Light Vehicle Market Growth: Commercial Vehicle _____________________________ Source: Orr & Boss; Axalta estimates Asia Pacific Latin America EMEA North America 3.6% 6.5% 2.6% 0.2% 3.0% 1.2 1.3 1.3 1.2 1.2 2.0 2.1 2.1 2.2 2.2 0.6 0.5 0.6 0.7 0.7 3.1 3.2 3.3 3.5 3.6 2015E 2016E 2017E 2018E 2019E (builds in millions) 7.8 ’15E – ‘19E CAGR 7.6 7.3 7.1 6.9 ($ in millions) Asia Pacific EMEA North America 4.6% 5.0% 5.3% 3.3% 4.5% $487 $494 $503 $525 $554 $414 $431 $457 $483 $508 $213 $218 $231 $243 $259 $1,186 $1,235 $1,302 $1,369 $1,422 2015E 2016E 2017E 2018E 2019E ’15E – ‘19E CAGR $2,743 _____________________________ Source: Orr & Boss; Axalta estimates Latin America $2,620 $2,493 $2,379 $2,300

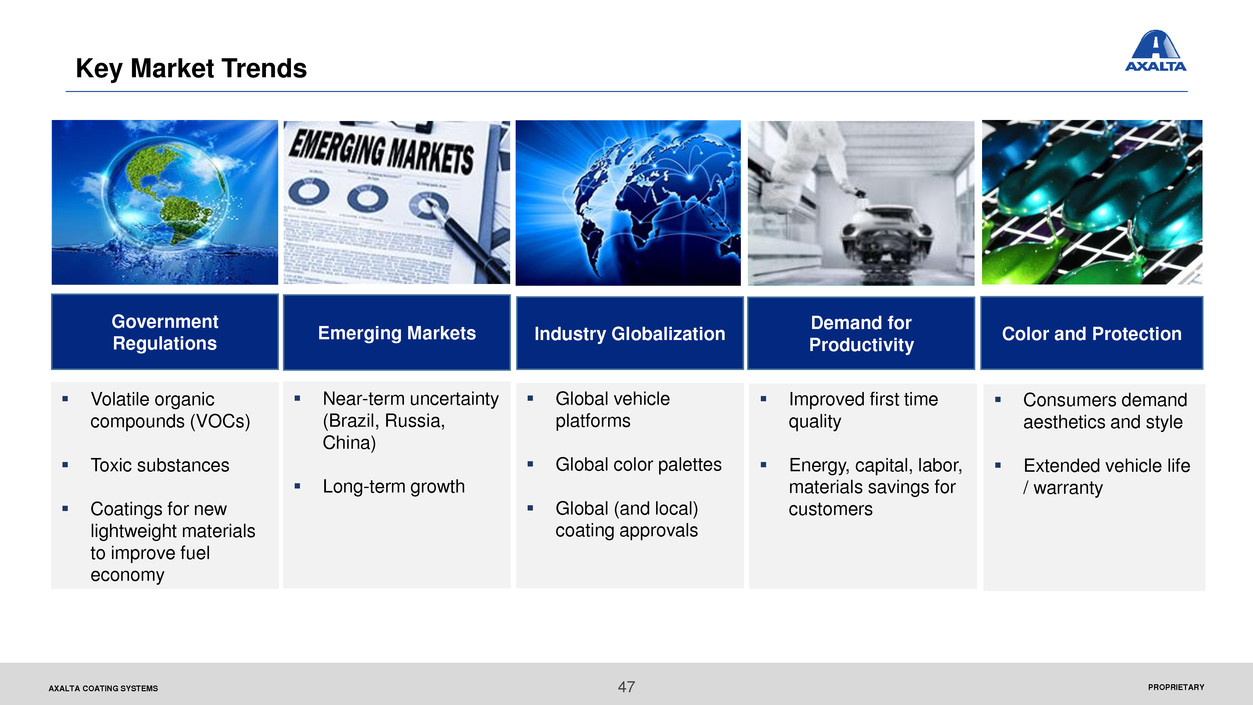

PROPRIETARY AXALTA COATING SYSTEMS 47 Key Market Trends Volatile organic compounds (VOCs) Toxic substances Coatings for new lightweight materials to improve fuel economy Government Regulations Emerging Markets Industry Globalization Demand for Productivity Color and Protection Near-term uncertainty (Brazil, Russia, China) Long-term growth Global vehicle platforms Global color palettes Global (and local) coating approvals Improved first time quality Energy, capital, labor, materials savings for customers Consumers demand aesthetics and style Extended vehicle life / warranty

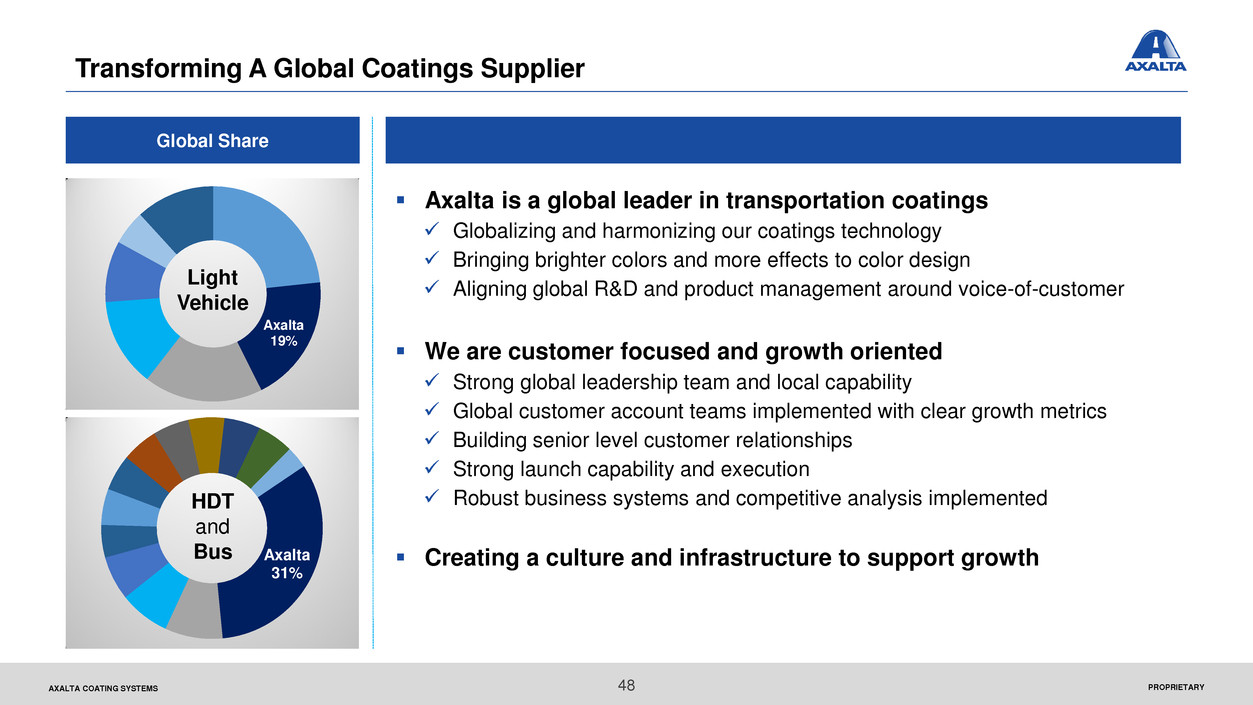

PROPRIETARY AXALTA COATING SYSTEMS Axalta 19% Transforming A Global Coatings Supplier Global Share 48 Axalta 31% Axalta is a global leader in transportation coatings Globalizing and harmonizing our coatings technology Bringing brighter colors and more effects to color design Aligning global R&D and product management around voice-of-customer We are customer focused and growth oriented Strong global leadership team and local capability Global customer account teams implemented with clear growth metrics Building senior level customer relationships Strong launch capability and execution Robust business systems and competitive analysis implemented Creating a culture and infrastructure to support growth HDT and Bus Light Vehicle

PROPRIETARY AXALTA COATING SYSTEMS Vision Is Above-Market Growth Gain share with existing customers Grow underserved customers and regions Align product technology to evolving customer and market needs Increase content per vehicle Leverage “what good looks like” into new regions, customers and markets Strategies Key Tactics / Programs Build capabilities in global and regional roles Expand decorative and functional coatings Best-in-class line service excellence Localize supply chain ensuring competitive cost structure Drive complexity management discipline The Axalta Way: “run it like we own it” 49

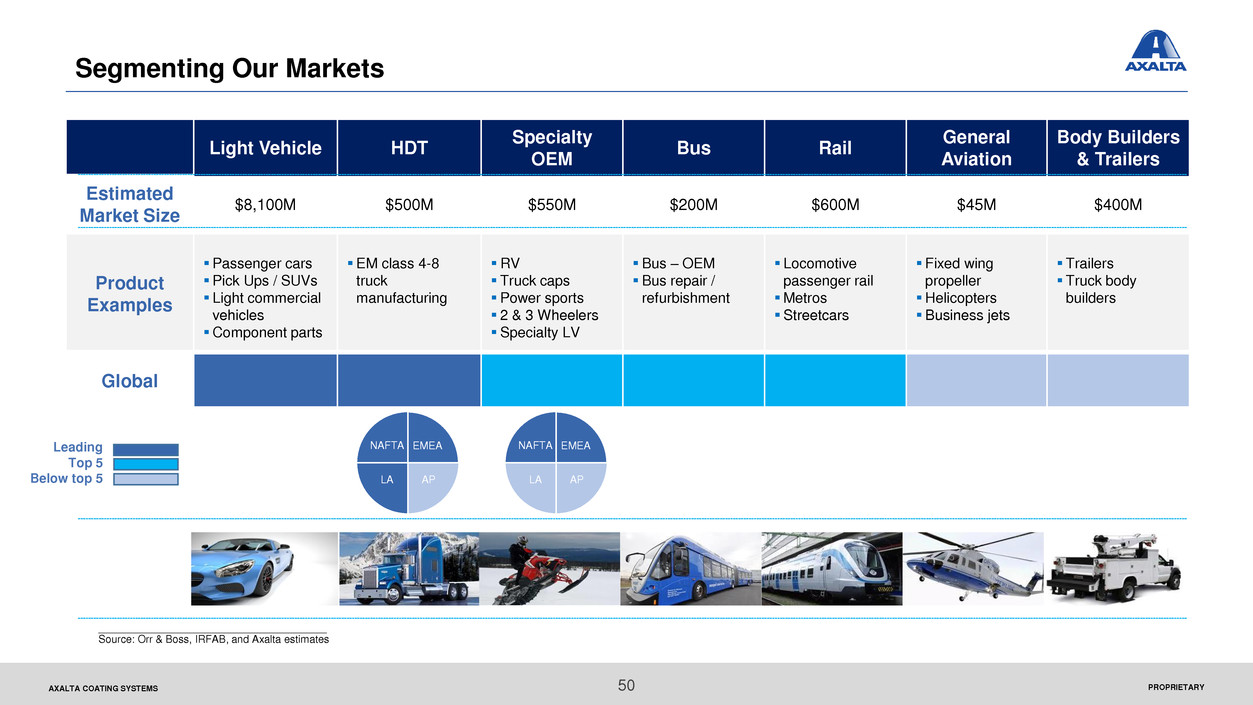

PROPRIETARY AXALTA COATING SYSTEMS Segmenting Our Markets Light Vehicle HDT Specialty OEM Bus Rail General Aviation Body Builders & Trailers Estimated Market Size $8,100M $500M $550M $200M $600M $45M $400M Product Examples Passenger cars Pick Ups / SUVs Light commercial vehicles Component parts EM class 4-8 truck manufacturing RV Truck caps Power sports 2 & 3 Wheelers Specialty LV Bus – OEM Bus repair / refurbishment Locomotive passenger rail Metros Streetcars Fixed wing propeller Helicopters Business jets Trailers Truck body builders Global EMEA AP LA NAFTA EMEA AP LA NAFTA _______________________________________ Source: Orr & Boss, IRFAB, and Axalta estimates Leading Top 5 Below top 5 50

PROPRIETARY AXALTA COATING SYSTEMS 51 We Are Growing With Segment Specific Strategies In Our Target Markets China expansion to mainstream and economy segments Leverage high speed rail success SprayFlex FS interior floor coatings Leverage global accounts Gain share in tier part suppliers China growth via Kinlita JV China HDT volume is three times NA Leverage Imron® branded offering Differentiation through strong HDT color leverage Developing a segment-focused distribution strategy Grow in automotive parts market China expansion through domestic OEMs AP expansion beyond China Gain approvals with underserved customers Strengthen service capability Expand 2-wheeler success in Brazil to other regions Leverage Imron® branded offering Segment-focused color strategy Light Vehicle Specialty OEM General Aviation Heavy Duty Truck (HDT) Bus and Rail Body Builders / Trailers Leverage approvals with Textron, Gulfstream, etc. Expand color palette for high value applications Align Imron® brands and offerings to segment Strategic alignments and capabilities

APPENDIX

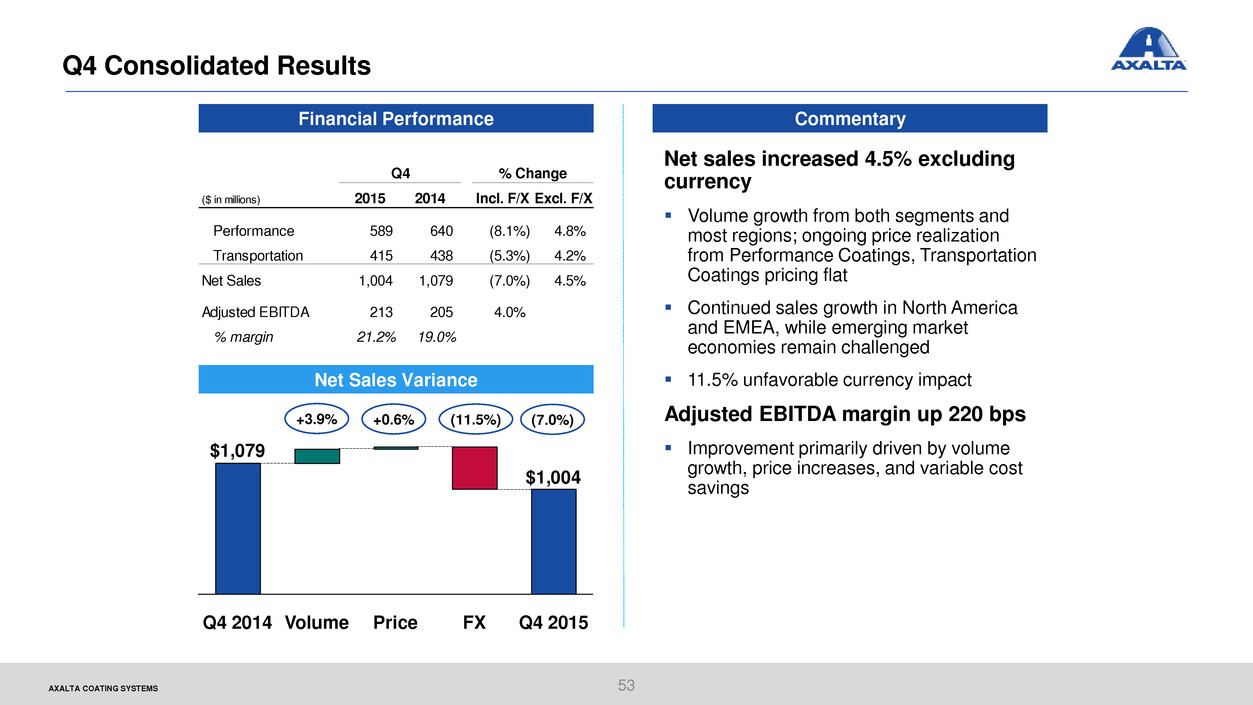

AXALTA COATING SYSTEMS Q4 Consolidated Results Financial Performance Commentary Net Sales Variance +3.9% +0.6% (11.5%) (7.0%) $1,004 $1,079 Q4 2015 FX Price Q4 2014 Volume 53 Net sales increased 4.5% excluding currency Volume growth from both segments and most regions; ongoing price realization from Performance Coatings, Transportation Coatings pricing flat Continued sales growth in North America and EMEA, while emerging market economies remain challenged 11.5% unfavorable currency impact Adjusted EBITDA margin up 220 bps Improvement primarily driven by volume growth, price increases, and variable cost savings ($ in millions) 2015 2014 Incl. F/X Excl. F/X Performance 589 640 (8.1%) 4.8% Transportation 415 438 (5.3%) 4.2% Net Sales 1,004 1,079 (7.0%) 4.5% Adjusted EBITDA 213 205 4.0% % margin 21.2% 19.0% Q4 % Change

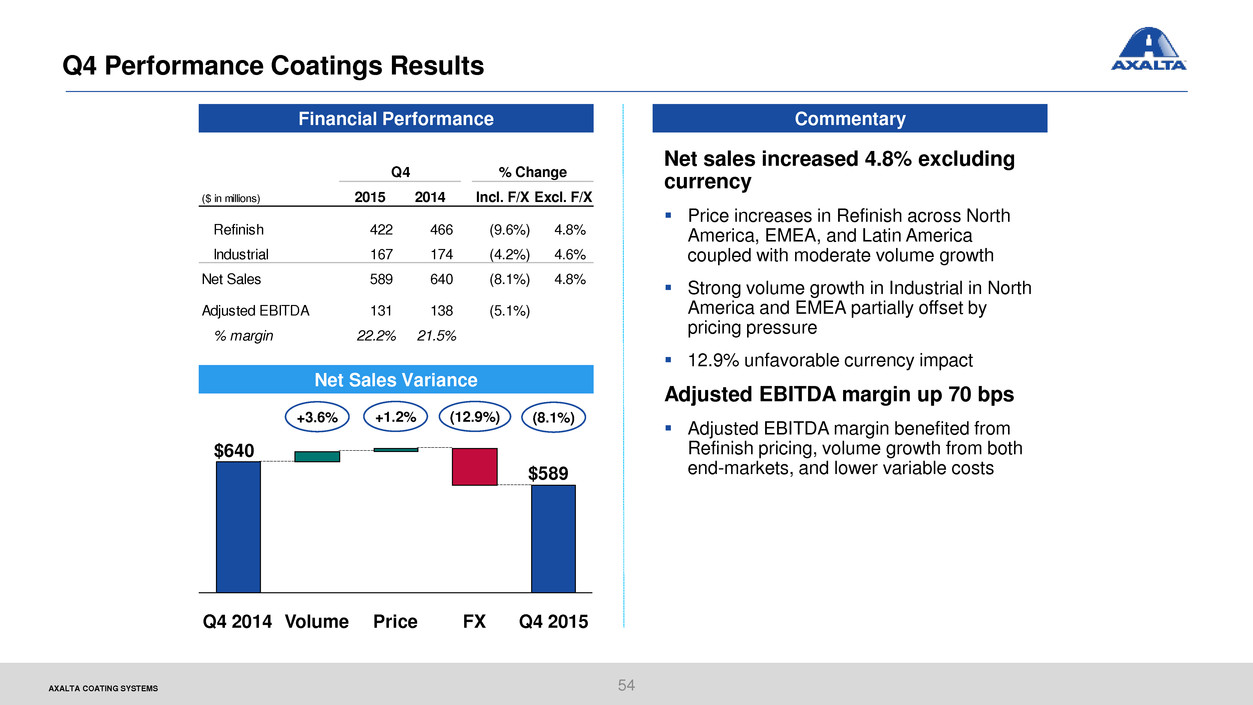

AXALTA COATING SYSTEMS Q4 Performance Coatings Results Financial Performance Commentary Net Sales Variance +3.6% +1.2% (12.9%) (8.1%) $589 $640 Q4 2015 Q4 2014 Volume FX Price 54 Net sales increased 4.8% excluding currency Price increases in Refinish across North America, EMEA, and Latin America coupled with moderate volume growth Strong volume growth in Industrial in North America and EMEA partially offset by pricing pressure 12.9% unfavorable currency impact Adjusted EBITDA margin up 70 bps Adjusted EBITDA margin benefited from Refinish pricing, volume growth from both end-markets, and lower variable costs Q4 ($ in millions) 2015 2014 Incl. F/X Excl. F/X Refinish 422 466 (9.6%) 4.8% Industrial 167 174 (4.2%) 4.6% Net Sales 589 640 (8.1%) 4.8% Adjusted EBITDA 131 138 (5.1%) % margin 22.2% 21.5% % Change

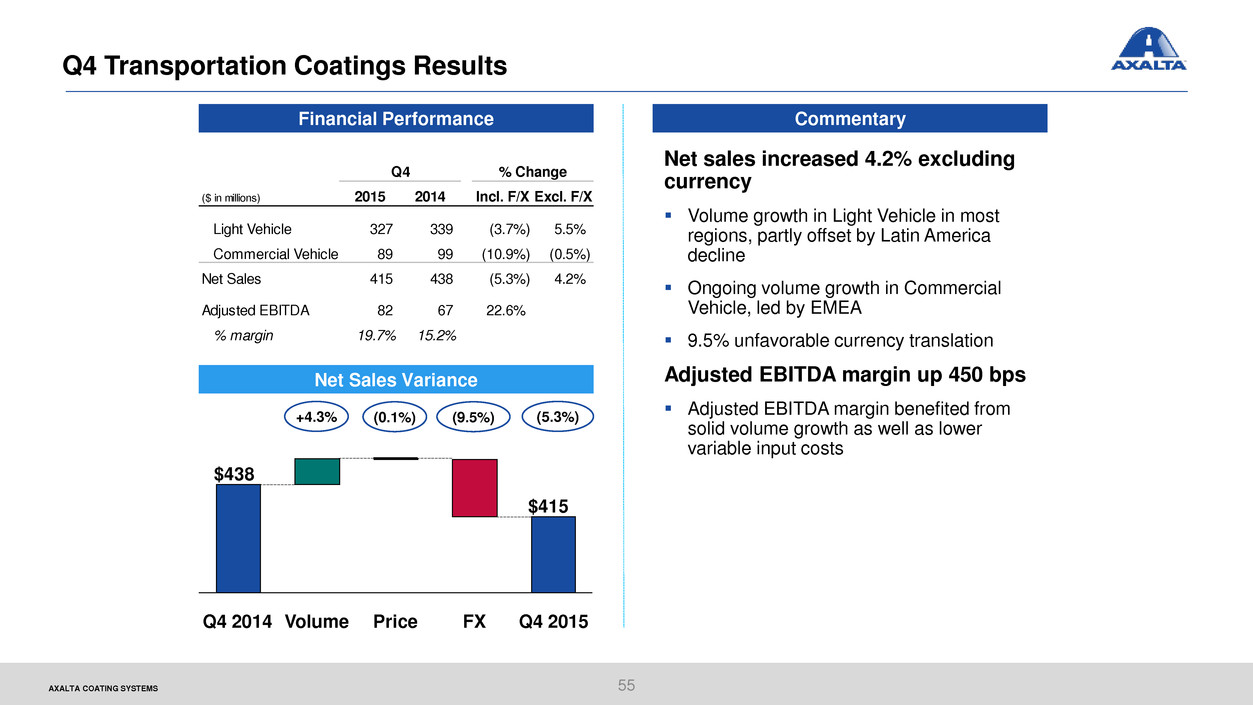

AXALTA COATING SYSTEMS Q4 Transportation Coatings Results Financial Performance Commentary Net Sales Variance +4.3% (0.1%) (5.3%) $415 $438 Volume Q4 2015 Price FX Q4 2014 55 Net sales increased 4.2% excluding currency Volume growth in Light Vehicle in most regions, partly offset by Latin America decline Ongoing volume growth in Commercial Vehicle, led by EMEA 9.5% unfavorable currency translation Adjusted EBITDA margin up 450 bps Adjusted EBITDA margin benefited from solid volume growth as well as lower variable input costs (9.5%) ($ in millions) 2015 2014 Incl. F/X Excl. F/X Light Vehicle 327 339 (3.7%) 5.5% Commercial Vehicle 89 99 (10.9%) (0.5%) Net Sales 415 438 (5.3%) 4.2% Adjusted EBITDA 82 67 22.6% % margin 19.7% 15.2% Q4 % Change

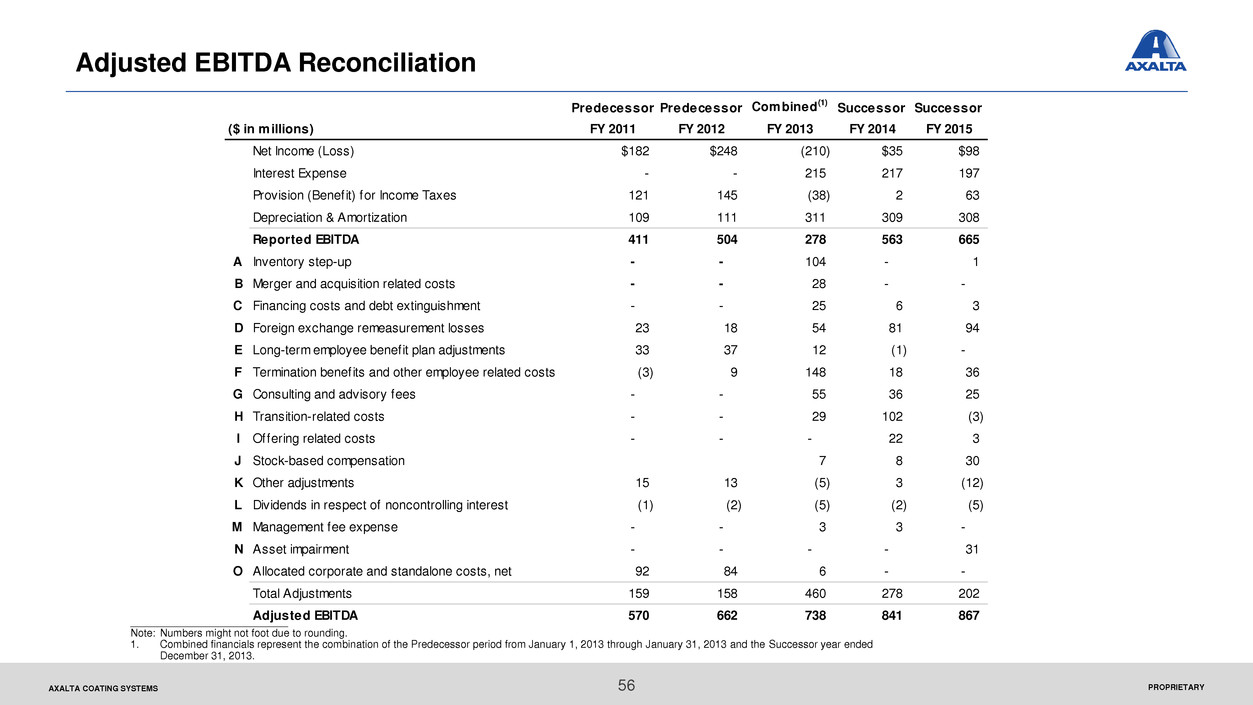

PROPRIETARY AXALTA COATING SYSTEMS Adjusted EBITDA Reconciliation 56 ___________________________ Note: Numbers might not foot due to rounding. 1. Combined financials represent the combination of the Predecessor period from January 1, 2013 through January 31, 2013 and the Successor year ended December 31, 2013. Predecessor Predecessor Combined (1) Successor Successor ($ in millions) FY 2011 FY 2012 FY 2013 FY 2014 FY 2015 Net Income (Loss) $182 $248 (210) $35 $98 Interest Expense - - 215 217 197 Provision (Benefit) for Income Taxes 121 145 (38) 2 63 Depreciation & Amortization 109 111 311 309 308 Reported EBITDA 411 504 278 563 665 A Inventory step-up - - 104 - 1 B Merger and acquisition related costs - - 28 - - C Financing costs and debt extinguishment - - 25 6 3 D Foreign exchange remeasurement losses 23 18 54 81 94 E Long-term employee benefit plan adjustments 33 37 12 (1) - F Termination benefits and other employee related costs (3) 9 148 18 36 G Consulting and advisory fees - - 55 36 25 H Transition-related costs - - 29 102 (3) I Offering related costs - - - 22 3 J Stock-based compensation 7 8 30 K Other adjustments 15 13 (5) 3 (12) L Dividends in respect of noncontrolling interest (1) (2) (5) (2) (5) M Management fee expense - - 3 3 - N Asset impairment - - - - 31 O Allocated corporate and standalone costs, net 92 84 6 - - Total Adjustments 159 158 460 278 202 Adjusted EBITDA 570 662 738 841 867

PROPRIETARY AXALTA COATING SYSTEMS 57 Adjusted EBITDA Reconciliation (cont’d) A. During the Successor years ended December 31, 2013 and 2015, we recorded a non-cash fair value adjustment associated with our acquisition accounting for inventories. These amounts increased cost of goods sold by $1 million and $104 million, respectively. B. In connection with the Acquisition, we incurred $28 million of merger and acquisition costs during the Successor year ended December 31, 2013. These costs consisted primarily of investment banking, legal and other professional advisory services costs. C. On August 30, 2012, we signed a debt commitment letter, which included the Bridge Facility. Upon the issuance of the Senior Notes and the entry into the Senior Secured Credit Facilities, the commitments under the Bridge Facility terminated. Commitment fees related to the Bridge Facility of $21 million and associated fees of $4 million were expensed upon the payment and termination of the Bridge Facility. In connection with the amendment to the Senior Secured Credit Facilities in February 2014, we recognized $3 million of costs. In addition to the credit facility amendment, we also incurred $3 million of losses on extinguishment of debt during both the years ended December 31, 2015 and 2014, respectively, which resulted directly from the pro-rata write offs of unamortized deferred financing costs and original issue discounts associated with the pay-downs of $100 million of principal on the New Dollar Term Loan in each year. D. Eliminates foreign exchange gains and losses resulting from the remeasurement of assets and liabilities denominated in foreign currencies, including a $19 million loss related to the Acquisition date settlement of a foreign currency contract used to hedge the variability of Euro-based financing for the Successor year ended December 31, 2013. E. For the Successor years ended December 31, 2015 and 2014, eliminates the non-service cost components of employee benefit costs. Additionally, we deducted a pension curtailment gain of $7 million recorded during the year ended December 31, 2014. For the Predecessor period January 1, 2013 through January 31, 2013 and the Predecessor years ended December 31, 2012 and 2011, eliminates (1) all U.S. pension and other long-term employee benefit costs that were not assumed as part of the Acquisition and (2) the non-service cost component of the pension and other long-term employee benefit costs. F. Represents expenses primarily related to employee termination benefits and other employee-related costs, including our initiative to improve the overall cost structure within the European region. Termination benefits include the costs associated with our headcount initiatives for establishment of new roles and elimination of old roles and other costs associated with cost saving opportunities that were related our Axalta Way cost savings initiatives in 2015. G. Represents fees paid to consultants, advisors, and other third-party professional organizations for professional services. Amounts incurred during 2015 primarily relate to our Axalta Way cost savings initiatives. Amounts incurred during the Successor years ended December 31, 2014 and 2013 relate to services rendered in conjunction with our transition from DuPont to a standalone entity. H. Represents charges associated with the transition from DuPont to a standalone entity, including branding and marketing, information technology related costs, and facility transition costs. I. Represents costs associated with the offering of our common shares in the Carlyle Offerings during 2015 and costs associated with the IPO, including a $13 million pre-tax charge associated with the termination of the management agreement with Carlyle Investment Management, L.L.C., an affiliate of Carlyle, upon the completion of the IPO during 2014.

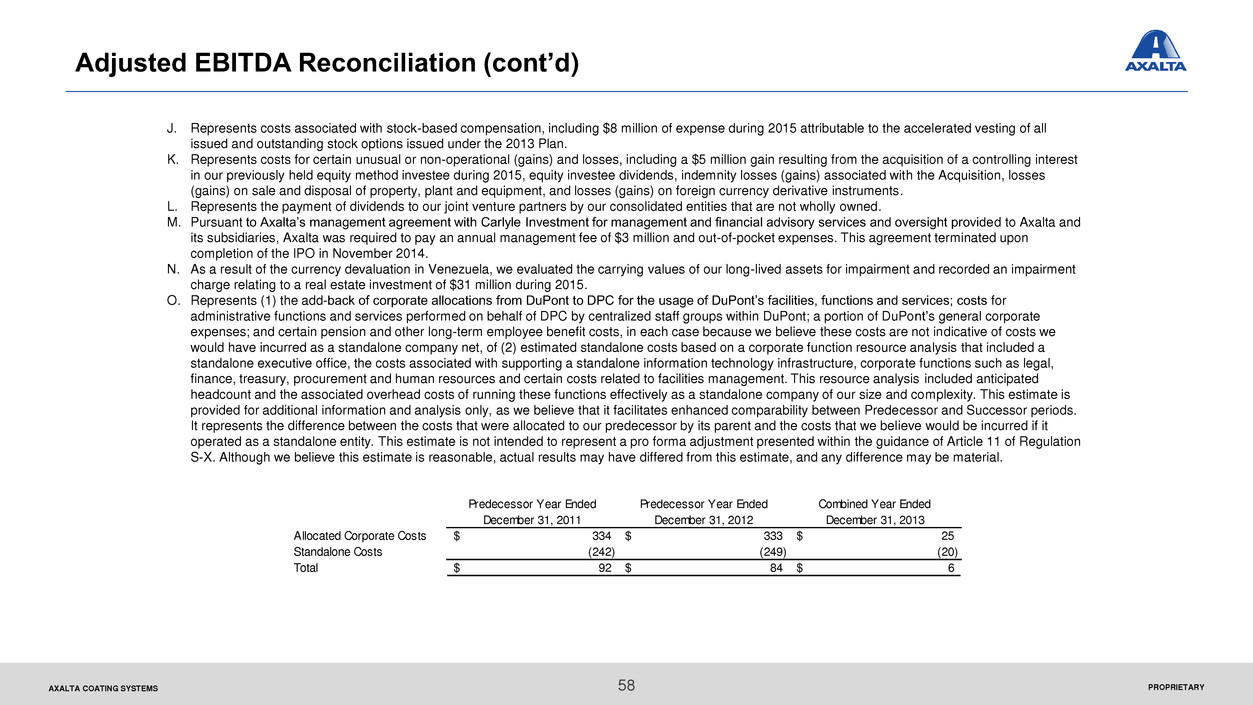

PROPRIETARY AXALTA COATING SYSTEMS 58 Adjusted EBITDA Reconciliation (cont’d) J. Represents costs associated with stock-based compensation, including $8 million of expense during 2015 attributable to the accelerated vesting of all issued and outstanding stock options issued under the 2013 Plan. K. Represents costs for certain unusual or non-operational (gains) and losses, including a $5 million gain resulting from the acquisition of a controlling interest in our previously held equity method investee during 2015, equity investee dividends, indemnity losses (gains) associated with the Acquisition, losses (gains) on sale and disposal of property, plant and equipment, and losses (gains) on foreign currency derivative instruments. L. Represents the payment of dividends to our joint venture partners by our consolidated entities that are not wholly owned. M. Pursuant to Axalta’s management agreement with Carlyle Investment for management and financial advisory services and oversight provided to Axalta and its subsidiaries, Axalta was required to pay an annual management fee of $3 million and out-of-pocket expenses. This agreement terminated upon completion of the IPO in November 2014. N. As a result of the currency devaluation in Venezuela, we evaluated the carrying values of our long-lived assets for impairment and recorded an impairment charge relating to a real estate investment of $31 million during 2015. O. Represents (1) the add-back of corporate allocations from DuPont to DPC for the usage of DuPont’s facilities, functions and services; costs for administrative functions and services performed on behalf of DPC by centralized staff groups within DuPont; a portion of DuPont’s general corporate expenses; and certain pension and other long-term employee benefit costs, in each case because we believe these costs are not indicative of costs we would have incurred as a standalone company net, of (2) estimated standalone costs based on a corporate function resource analysis that included a standalone executive office, the costs associated with supporting a standalone information technology infrastructure, corporate functions such as legal, finance, treasury, procurement and human resources and certain costs related to facilities management. This resource analysis included anticipated headcount and the associated overhead costs of running these functions effectively as a standalone company of our size and complexity. This estimate is provided for additional information and analysis only, as we believe that it facilitates enhanced comparability between Predecessor and Successor periods. It represents the difference between the costs that were allocated to our predecessor by its parent and the costs that we believe would be incurred if it operated as a standalone entity. This estimate is not intended to represent a pro forma adjustment presented within the guidance of Article 11 of Regulation S-X. Although we believe this estimate is reasonable, actual results may have differed from this estimate, and any difference may be material. Predecessor Year Ended D mber 31, 2011 Predecessor Year Ended D mber 31, 2012 Combined Year Ended December 31, 2013 Allocated Corporate Costs 334$ 333$ 25$ Standalone Costs (242) (249) ( 0) Total 9$ 84$ 6$